- Nov 26, 2024

In the fast-paced world of manufacturing, speed and efficiency are critical factors that determine a company’s competitiveness. Rapid tooling has emerged as a transformative technology, offering significant advantages over traditional tooling methods. By leveraging advanced techniques and materials, rapid tooling enables manufacturers to produce prototypes and parts faster, catering to industries that demand quick turnaround times. Let’s explore why rapid tooling is a time-saving solution and how it benefits industries like automotive, aerospace, and consumer goods.

What is Rapid Tooling?

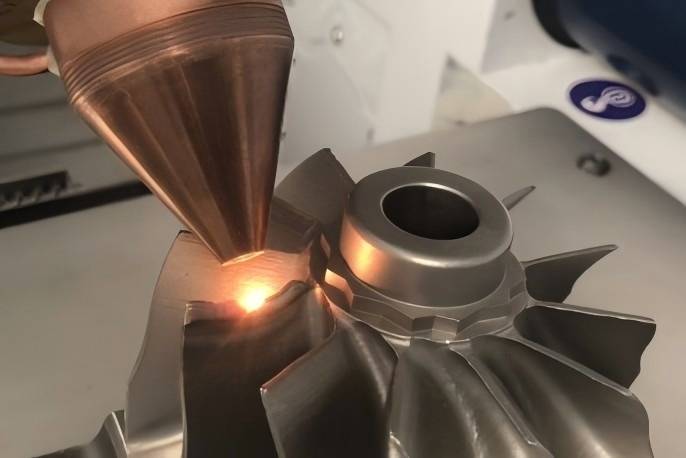

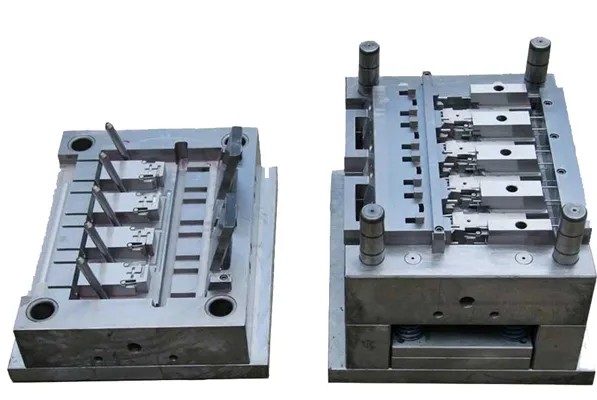

Rapid tooling, often referred to as bridge tooling or prototype tooling, is a process that uses advanced manufacturing technologies such as 3D printing, CNC machining, and injection molding to create molds quickly. Unlike traditional tooling, which can take weeks or months to produce due to the extensive machining and assembly required, rapid tooling significantly reduces lead times. This is particularly beneficial for low-volume prototype production, where time-sensitive projects demand quick iterations.

Key Benefits of Rapid Tooling Over Traditional Tooling

1. Reduced Lead Time

One of the most significant advantages of rapid tooling is its ability to drastically shorten the production timeline. Traditional tooling involves labor-intensive processes such as detailed design, precision machining, and polishing. In contrast, rapid mold manufacturing employs automated processes like additive manufacturing to build molds directly from CAD models, cutting down weeks of preparation to just a few days.

2. Cost-Effectiveness for Prototyping

For small-batch or low-volume prototype production, the cost of traditional tooling can be prohibitive. Rapid tooling offers a cost-efficient alternative by minimizing material waste and reducing manual labor. By working with experienced rapid mold manufacturers, companies can ensure that they get high-quality molds at a fraction of the time and cost of traditional methods.

3. Design Flexibility and Quick Iterations

Rapid tooling allows for greater design flexibility, enabling manufacturers to test multiple iterations of a product without the need to rework an entire mold. This is particularly useful during the product development phase, where fine-tuning designs is essential to achieve optimal functionality. With the ability to make changes quickly, companies can bring their products to market faster and with higher confidence.

4. Enhanced Material Options

Modern rapid mold manufacturing processes accommodate a wide range of materials, making it easier to test different material properties in prototypes. This capability is especially important for industries that require materials with specific characteristics, such as heat resistance or durability.

5. Scalability for Low-Volume Production

While traditional tooling is designed for high-volume production runs, rapid tooling excels in low-volume prototype production. This scalability allows businesses to test market viability or fulfill niche demands without committing to expensive large-scale tooling investments.

Applications of Rapid Tooling

Automotive Industry: Rapid tooling is widely used to produce prototypes of car components, allowing manufacturers to test functionality and fit before committing to mass production.

Aerospace: The aerospace sector benefits from rapid tooling by quickly producing lightweight and durable parts for testing and validation.

Consumer Goods: Rapid tooling enables companies to create prototypes of consumer products, such as electronics and household items, to gather feedback and make improvements before launch.

How to Choose the Right Rapid Mold Manufacturers

Selecting the right rapid mold manufacturers is crucial to achieving the benefits of rapid tooling. Look for companies that offer:

Expertise in advanced manufacturing techniques.

A proven track record in delivering high-quality molds.

Flexibility in handling low-volume prototype production.

Fast turnaround times and responsive customer service.

By partnering with reliable rapid mold manufacturers, businesses can ensure they stay ahead of the competition and bring innovative products to market more quickly. Rapid tooling has revolutionized the manufacturing landscape by significantly reducing lead times and costs compared to traditional tooling methods. Its versatility, efficiency, and scalability make it an ideal choice for industries that demand quick and flexible solutions. Whether it’s for low-volume prototype production or testing new product designs, rapid tooling is a game-changer for modern manufacturing. By embracing this technology and collaborating with experienced rapid mold manufacturers, businesses can achieve faster time-to-market, reduced costs, and improved product quality—ensuring they remain competitive in today’s dynamic market.