- Jul 01, 2025

When developing a new product, the prototyping phase is crucial. It allows businesses to test and refine designs before moving to full-scale production. However, this phase can often be expensive, especially for small businesses or startups with limited budgets. Affordable CNC milling has emerged as a game-changing technology, offering precision, speed, and cost-effectiveness for prototyping processes. Whether you’re working in the aerospace, automotive, or consumer goods industries, CNC milling can streamline your prototyping process while delivering high-quality results.

This article will explore how affordable CNC milling can benefit your prototyping process, covering the advantages, applications, and practical insights into using CNC technology for small-scale prototyping.

What is CNC Milling?

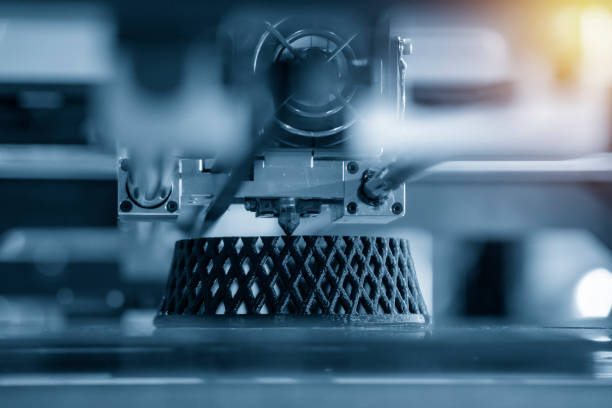

CNC milling (Computer Numerical Control milling) is a precision machining process that uses computer-controlled equipment to shape materials, such as metals, plastics, and composites, into specific forms. The process involves a rotating cutting tool that removes material from a workpiece, allowing manufacturers to create parts with complex geometries, intricate details, and fine features.

Affordable CNC milling for prototyping refers to the use of CNC milling technology that is cost-effective, especially for small batches or low-volume runs. With the rise of small-scale CNC milling services, companies can now access high-quality prototyping solutions without the need for expensive tooling or large minimum order quantities.

How Affordable CNC Milling Benefits Your Prototyping Process

1. Cost-Effective for Small-Scale Production

Traditional prototyping methods like injection molding or casting often require costly molds, extensive setup times, and high initial investments, making them impractical for small-run projects or prototype testing. Affordable CNC milling eliminates the need for expensive tooling by using computer-controlled machines that can produce parts directly from a CAD design.

Since there are no expensive molds or tooling costs involved, small businesses and startups can produce small batches or even single prototypes without the financial burden of traditional manufacturing methods. This makes CNC milling a more accessible option for companies with limited resources, allowing them to prototype designs quickly and economically.

2. Faster Turnaround Times

Time is often of the essence when developing new products. The ability to quickly iterate on a prototype can be the difference between staying ahead of the competition or falling behind. CNC milling significantly reduces the turnaround time for prototyping.

Once the design is finalized in CAD (Computer-Aided Design), the CNC machine can begin production almost immediately. Unlike traditional methods such as manual machining, which can take hours or even days to complete a part, CNC milling can produce high-precision parts in a fraction of the time. This quick turnaround allows designers and engineers to test prototypes, make adjustments, and move on to the next phase faster.

3. Precision and Accuracy

In prototyping, precision is critical. Traditional methods like manual machining and casting can introduce human error, inconsistencies in material removal, and variations in part quality. Affordable CNC milling offers unmatched precision, allowing manufacturers to create parts with tight tolerances and consistent quality every time.

CNC machines are capable of machining parts to within fractions of a millimeter, which is ideal for industries like aerospace, automotive, and medical devices that require high-performance prototypes with exact specifications. Whether you need parts with intricate geometries, small-scale CNC milling allows you to produce components that fit perfectly, ensuring that prototypes can be tested for form, fit, and function.

4. Material Versatility

One of the standout benefits of CNC milling is its ability to work with a wide variety of materials. Affordable CNC milling for prototyping can accommodate metals like aluminum, steel, and titanium, as well as plastics, composites, and even wood. This versatility allows manufacturers to choose the ideal material for their prototypes based on the intended use.

For instance, you can use aluminum for lightweight prototypes in the automotive industry, stainless steel for medical devices, or plastics for consumer goods. With small-scale CNC milling, you can experiment with different materials to test the performance, durability, and aesthetics of your prototypes without committing to large-scale production runs.

5. Design Flexibility and Complexity

When prototyping with traditional methods, there are often limitations to the complexity of the designs that can be achieved. For example, injection molding and casting are best suited for simpler shapes and designs, and any changes to the prototype can require costly retooling.

CNC milling offers unmatched design flexibility. It can produce highly complex and intricate parts with ease, enabling manufacturers to create prototypes with complicated geometries, detailed features, and tight tolerances. CNC milling is particularly beneficial when prototyping parts with undercuts, cavities, or fine details that would be difficult or impossible to achieve with traditional methods.

For businesses in industries like aerospace, automotive, and electronics, where complex and customized parts are often required, CNC milling allows engineers to prototype highly detailed and sophisticated components quickly and affordably.

Applications of Affordable CNC Milling in Prototyping

CNC milling is widely used across various industries, and its affordable nature makes it especially useful for small-scale prototyping. Below are some key applications where small-scale CNC milling can offer significant advantages:

1. Aerospace and Defense

In the aerospace and defense industries, prototypes need to be highly precise and capable of performing under extreme conditions. CNC milling is often used to create parts like brackets, enclosures, engine components, and other critical pieces. Affordable CNC milling allows aerospace engineers to test prototypes quickly, ensuring they meet stringent performance and safety standards.

2. Automotive Industry

The automotive industry frequently uses CNC milling for prototyping parts like engine components, chassis, interior parts, and other mechanical systems. Affordable CNC milling for prototyping allows automakers to iterate on designs rapidly and test their prototypes in real-world conditions. This helps reduce time-to-market and ensures the final product meets both performance and regulatory requirements.

3. Consumer Goods and Electronics

In the consumer goods and electronics industries, prototyping is essential for testing functionality, ergonomics, and aesthetics before mass production. CNC milling enables designers to create prototypes with fine details and specific functionalities, ensuring that the product works as intended. For example, affordable CNC milling is often used to create prototypes for smartphone housings, home appliances, and wearable technology.

4. Medical Device Manufacturing

The medical device industry demands high precision and tight tolerances for the prototypes used in the development of new products. Affordable CNC milling is essential in this field for creating prototypes of components such as surgical instruments, implants, and medical devices. CNC milling ensures that prototypes can be tested for performance, safety, and regulatory compliance before moving to production.

CNC Milling vs. Traditional Prototyping Methods: A Comparison

1. Cost Comparison

Affordable CNC milling offers a more cost-effective solution than traditional methods like injection molding, which requires expensive molds. CNC milling, by contrast, eliminates the need for such tooling, making it more cost-effective for small batches or prototype runs. The initial setup costs are also lower, allowing small businesses and startups to access high-quality prototyping wit

2. Speed Comparison

While traditional prototyping methods like casting or manual machining can be slower due to complex setups and tool changes, CNC milling machines can produce parts much more quickly and with greater consistency. The ability to quickly adjust designs or make minor changes is another major advantage of CNC milling for rapid prototyping.

3. Quality Comparison

CNC milling delivers superior precision and accuracy compared to many traditional methods. It provides consistent results and allows for complex designs that would be difficult or expensive to produce using conventional techniques like casting or injection molding. Traditional methods may also result in variations in part quality due to human error or material inconsistencies, while CNC milling ensures high-quality results with minimal tolerance variations.

Conclusion

Affordable CNC milling for prototyping offers a wide range of benefits that can significantly improve the prototyping process. It is cost-effective, quick, precise, and versatile, making it the ideal solution for industries ranging from aerospace to consumer goods. Whether you're creating a small batch of parts or testing out complex designs, CNC milling provides the tools you need to accelerate your prototyping process without compromising quality.

With the ability to produce high-quality, complex prototypes in a matter of days rather than weeks, CNC milling helps businesses stay competitive by reducing time-to-market and allowing for rapid design iterations. For small businesses, startups, and established companies alike, affordable CNC milling provides an excellent pathway for successful product development and prototyping.

By choosing CNC milling for your prototyping needs, you can ensure that your product designs are both functional and market-ready while staying within your budget. Whether you’re in the aerospace, automotive, or electronics industry, CNC milling offers the precision, speed, and cost-effectiveness required to bring your prototypes to life.