Case Study: How to Develop Diving Goggle Housing?

Laser Rapid Prototyping (LRP) technology is a rapid prototyping technology that

Laser Rapid Prototyping (LRP) technology is a rapid prototyping technology that uses laser beams to melt powder materials into shape. It is widely used in 3D printing, aerospace, medical equipment and other fields. In daily life, laser rapid prototyping is also widely used.

1. Personalized customization: People can use laser rapid prototyping technology to make their own personalized products, such as handicrafts, jewelry, etc.;

2. 3D printed food: By using special laser rapid prototyping equipment, realistic food models or simulated dishes can be produced, allowing people to better understand and try different cuisines;

3. Repair of handmade products: The damaged parts of handmade products can be repaired using laser rapid prototyping technology to restore them to their original appearance;

4. Stationery production: Students can use laser rapid prototyping technology to make various stationery, such as pen holders, notebooks, etc.;

5. Home decoration: Laser rapid prototyping technology can also be used to make home decorations, such as vases, ornaments, etc.

In short, laser rapid prototyping technology is widely used in life, providing people with more choices and convenience

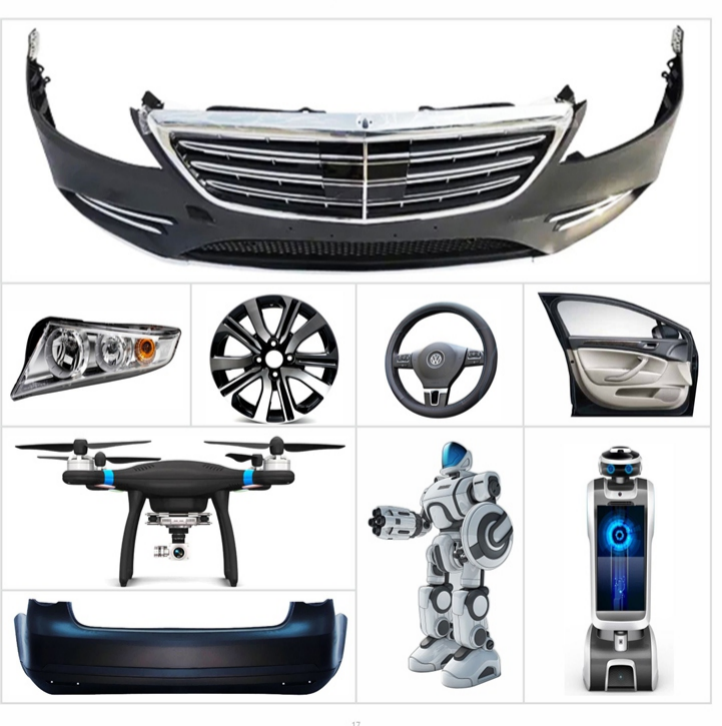

At the same time, laser rapid manufacturing (LRM) is an advanced manufacturing technology that forms a three-dimensional structure by heating powdered materials to high temperatures and rapidly cooling them. This technology has broad application prospects in the field of automotive mold manufacturing.

First of all, laser rapid prototyping can be used to produce high-precision, complex-shaped parts. Traditional mold manufacturing methods often require a lot of time and manpower, and are prone to errors and quality problems. The use of laser rapid prototyping technology can directly generate parts based on CAD models, avoiding the uncertainty and high error rate caused by manual operations; at the same time, due to the use of high-temperature rapid prototyping, the accuracy and surface quality of parts have also been improved. .

Secondly, laser rapid prototyping can also achieve personalized customization. Traditional mold manufacturing can usually only produce standardized products and cannot meet the needs of different customers. However, laser rapid prototyping can be customized according to user needs and quickly produce parts or overall molds that meet the requirements. This not only improves production efficiency, but also better meets market demand.

In addition, with the development of new energy vehicles, battery modules have become one of the key components. Laser rapid prototyping can produce complex battery module structures through methods such as powder metallurgy, thereby reducing costs and improving performance.

To sum up, the application prospects of laser rapid prototyping technology in automobile mold manufacturing are very broad.