- Dec 26, 2023

In the intricate realm of manufacturing, precision is a non-negotiable cornerstone. CNC (Computer Numerical Control) machining services have emerged as the pinnacle of precision engineering, showcasing an intricate dance of technology and methodology to produce components with unparalleled accuracy. This article delves into the meticulous processes employed by CNC machining services to guarantee exacting precision in the fabrication of intricate and complex parts.

1. Digital Blueprint Translation:

The precision journey commences with the translation of design blueprints into a digital format. CNC machining services leverage sophisticated software to convert intricate designs into precise digital code. This digital blueprint serves as the guiding force for the entire CNC machining process.

2. Automated Excellence:

At the heart of CNC machining lies automation, eliminating the variability introduced by manual operations. Once the digital program is set, CNC machines autonomously execute a series of intricate toolpath movements with exacting precision. The automated nature of the process ensures consistency across every iteration.

3. Velocity and Precision:

Speed is not just a byproduct; it's a deliberate choice in CNC machining. High-speed CNC machines execute rapid movements with precision, minimizing the impact of external factors like temperature fluctuations. The combination of velocity and precision ensures the efficient and accurate completion of the machining process.

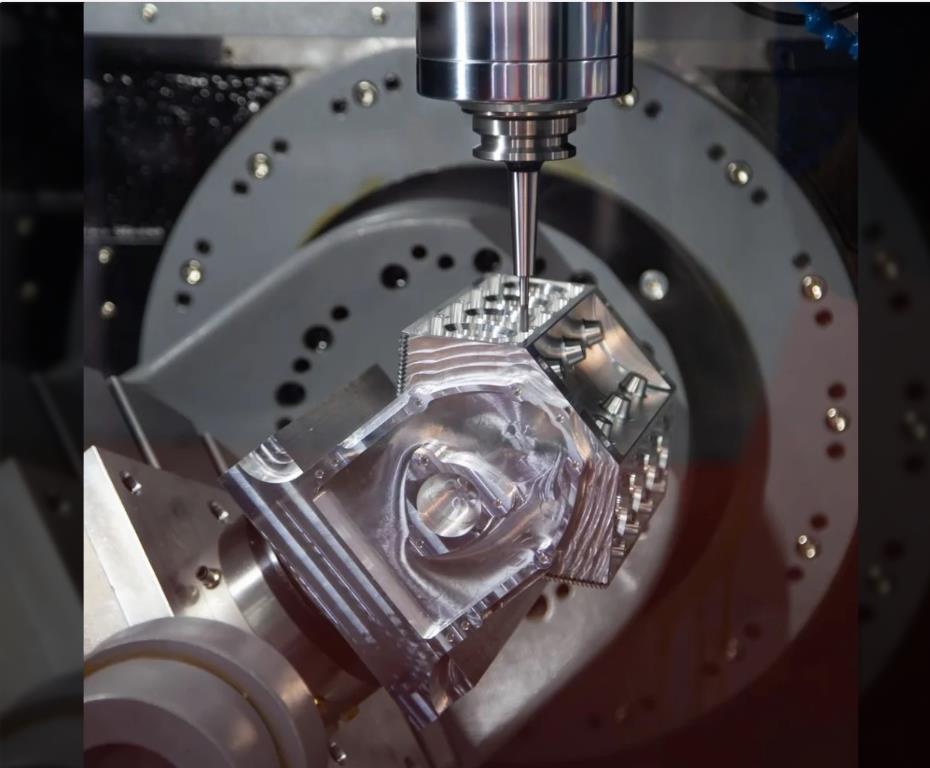

4. Multi-Axis Machining Mastery:

CNC machining services often employ multi-axis machining, allowing for simultaneous movement in multiple directions. This capability is indispensable for crafting components with complex geometries, as it enables precision in various planes and angles.

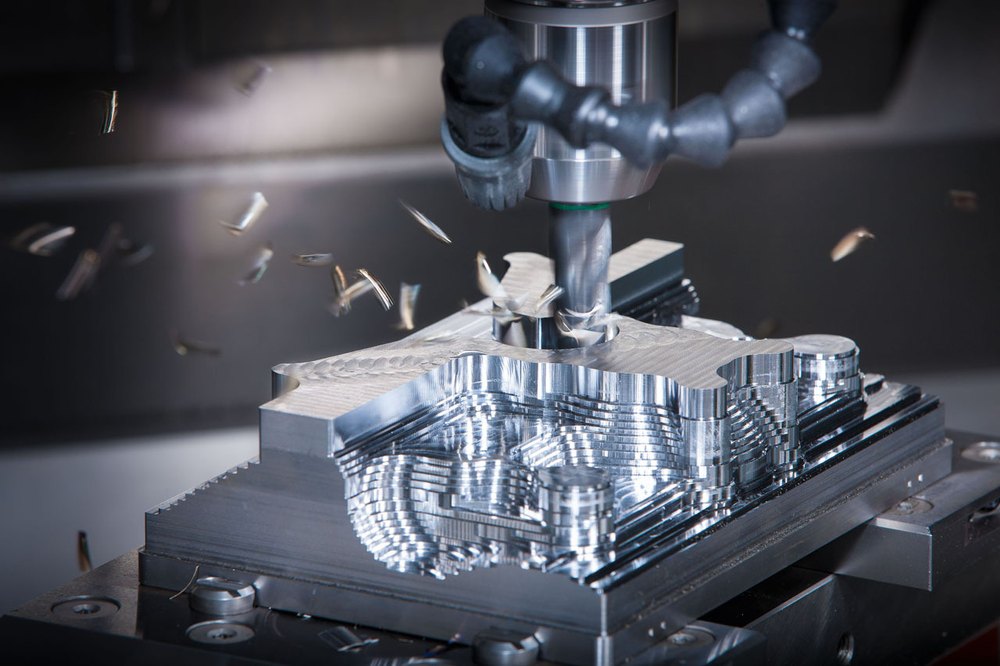

5. Cutting-Edge Tooling Technology:

The precision of CNC machining is intricately tied to the quality of the tools utilized. CNC machines employ cutting-edge tooling technologies, such as high-speed, precision drills and end mills. The selection of tools is tailored to the specific requirements of the material being machined and the intricacy of the design.

6. In-Process Quality Control:

Unlike traditional machining, where quality control is typically performed after the completion of the process, CNC machining integrates real-time quality control measures. In-process measurement systems continuously monitor and verify the dimensions of the workpiece during machining. Immediate feedback enables adjustments to maintain precision throughout.

7. Reproducibility and Consistency:

A hallmark of CNC machining is its ability to replicate identical components with unwavering consistency. Once the precision parameters are established, CNC machines can reproduce the same level of accuracy across large production runs, ensuring uniformity in every piece manufactured.

8. Material Adaptability and Tight Tolerances:

CNC machining services exhibit a remarkable adaptability to a diverse range of materials, from metals to plastics. Moreover, CNC machining excels in achieving tight tolerances, meeting the exacting requirements of industries where precision is not just a preference but an imperative.

In conclusion, CNC machining services represent the zenith of precision engineering. Through meticulous digital programming, seamless automation, high-speed operations, and advanced tooling, CNC machining ensures that precision isn't a mere outcome but an integral part of the manufacturing ethos. As CNC machining continues to evolve, its role in pushing the boundaries of precision remains a testament to the ongoing transformation of modern manufacturing