- Mar 25, 2024

Manufacturing prototyping serves as a critical phase in the product development cycle, allowing businesses to validate designs, assess functionality, and identify potential improvements before full-scale production. Rapid CNC prototyping, a subset of manufacturing prototyping, leverages advanced machining techniques to quickly produce high-quality prototypes. In this article, we delve into the concept of manufacturing prototyping, focusing on the role of rapid CNC machining in accelerating innovation and enhancing product development processes.

Understanding Manufacturing Prototyping:

Manufacturing prototyping involves the creation of physical prototypes that represent the intended final product. These prototypes are used for testing, evaluation, and validation purposes, providing valuable insights into design feasibility, functionality, and performance. By iteratively refining prototypes based on feedback and testing results, manufacturers can minimize risks, optimize designs, and ultimately deliver superior products to the market.

Rapid CNC Prototyping:

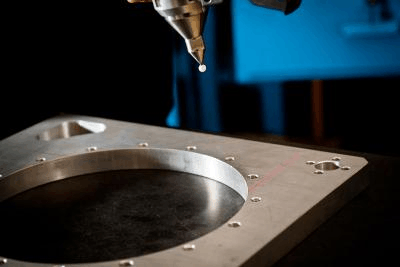

Rapid CNC prototyping combines the speed and precision of computer numerical control (CNC) machining with rapid prototyping techniques to produce prototypes efficiently and cost-effectively. Unlike traditional prototyping methods that may require extensive tooling or manual labor, rapid CNC prototyping utilizes automated machining processes to transform digital designs into physical prototypes with unparalleled accuracy and detail.

Key Advantages of Rapid CNC Prototyping:

1. Speed: Rapid CNC prototyping offers significantly faster turnaround times compared to conventional prototyping methods. With automated machining processes and advanced software capabilities, manufacturers can produce prototypes in days rather than weeks or months, accelerating product development timelines.

2. Precision: CNC machining ensures exceptional precision and repeatability, allowing for the creation of highly detailed prototypes with tight tolerances. This level of accuracy enables manufacturers to assess form, fit, and function accurately, leading to more reliable testing outcomes.

3. Versatility: Rapid CNC prototyping supports a wide range of materials, including metals, plastics, and composites, offering flexibility in prototype development. Manufacturers can choose materials that closely mimic the properties of the final production materials, providing more realistic testing conditions.

4. Cost-Effectiveness: While rapid CNC prototyping may involve upfront investment in machinery and software, it offers long-term cost savings by reducing prototyping lead times and minimizing material waste. By optimizing production processes and streamlining workflows, manufacturers can achieve greater efficiency and competitiveness in the market.

5. Iterative Design: The speed and flexibility of rapid CNC prototyping empower manufacturers to iterate and refine designs quickly based on feedback and testing results. This iterative approach fosters innovation, allowing for continuous improvement and optimization throughout the product development cycle.

Applications of Rapid CNC Prototyping:

1.Rapid CNC prototyping finds applications across various industries, including aerospace, automotive, healthcare, consumer electronics, and more. Common use cases include:

2.Conceptual Modeling: Creating visual representations of product concepts for stakeholder review and feedback.

3.Functional Testing: Evaluating the performance and functionality of prototypes under real-world conditions to identify potential issues or improvements.

4.Tooling and Fixtures: Producing custom tooling, jigs, and fixtures for manufacturing processes to enhance efficiency and accuracy.

5.Custom Parts Production: Manufacturing low-volume or specialized parts with complex geometries and tight tolerances for niche markets or custom applications.

Manufacturing prototyping, particularly rapid CNC prototyping, plays a pivotal role in driving innovation, reducing time to market, and ensuring the success of new product development initiatives. By harnessing the speed, precision, and versatility of CNC machining technologies, manufacturers can iterate designs rapidly, mitigate risks, and deliver exceptional products that meet or exceed customer expectations. As the manufacturing landscape continues to evolve, embracing rapid CNC prototyping will remain essential for staying competitive and meeting the demands of an ever-changing market.