- Jun 13, 2024

1. Service Provider Certification

When you compare and collect different cnc machining suppliers, you must first visit the certifications they have obtained. Whether they have an important certification ISO 9001. ISO 9001 is a standard that specifies the requirements of a quality management system. CNAC machine shops that are certified to ISO 9001 strictly comply with legal and regulatory requirements to ensure high-quality machining services. Once you have confirmed that the certification of the machining shop meets your requirements, you must determine the type of CNC machining equipment they have in their factory.

2. Type of machining equipment

The type of CNC machine used to create prototype (or production) parts has a significant impact on the quality of the parts. There are many types of CNC machines, which are usually classified according to the number of axes that can be operated, such as 2-axis, 3-axis, 4-axis, and 5-axis CNC machines. 5-axis CNC machines are more advanced than 2-axis, 3-axis, and 4-axis CNC machines. They provide higher precision, better surface finish, and are able to process more complex shapes. Although not all parts require 5-axis machining, for sufficiently complex parts, 5-axis CNC machines may be the ideal solution. Third-party processing suppliers that use advanced CNC machining technology in their factories work hard to ensure the high quality of the parts they process. But when choosing a third-party processing supplier, you should not only focus on the technical level of the CNC machine tools. The quality of the parts also depends to a large extent on the professional level of the CNC operators who operate these machines. In other words, the skills and experience of the CNC operators are also key factors in ensuring the high quality of machined parts.

3. Quality of CNC machining

Although cnc machining manufacturers often claim to have various certifications and state-of-the-art processing equipment, it is not uncommon for customers to receive low-quality and unusable CNC machined parts. Often, these problems can be traced back to technical problems of CNC machine operators. In fact, the skill gap of CNC machine operators is a widespread problem. Many operators can only gradually accumulate experience through "hard lessons", but are often prone to making the same processing mistakes repeatedly. To complicate matters, many machine shops lack a standardized quality management system to check the parts manufactured by operators or technicians. It is crucial to avoid choosing these types of suppliers.

4. Top CNC machine shops perform three types of inspections

Top machine shops usually perform three types of inspections at different stages of a manufacturing project:

Machine operator inspection: an inspection performed during or immediately after processing, which is the responsibility of the operator. This involves using simple measuring tools such as go/no-go gauges and micrometers to identify tolerance issues.

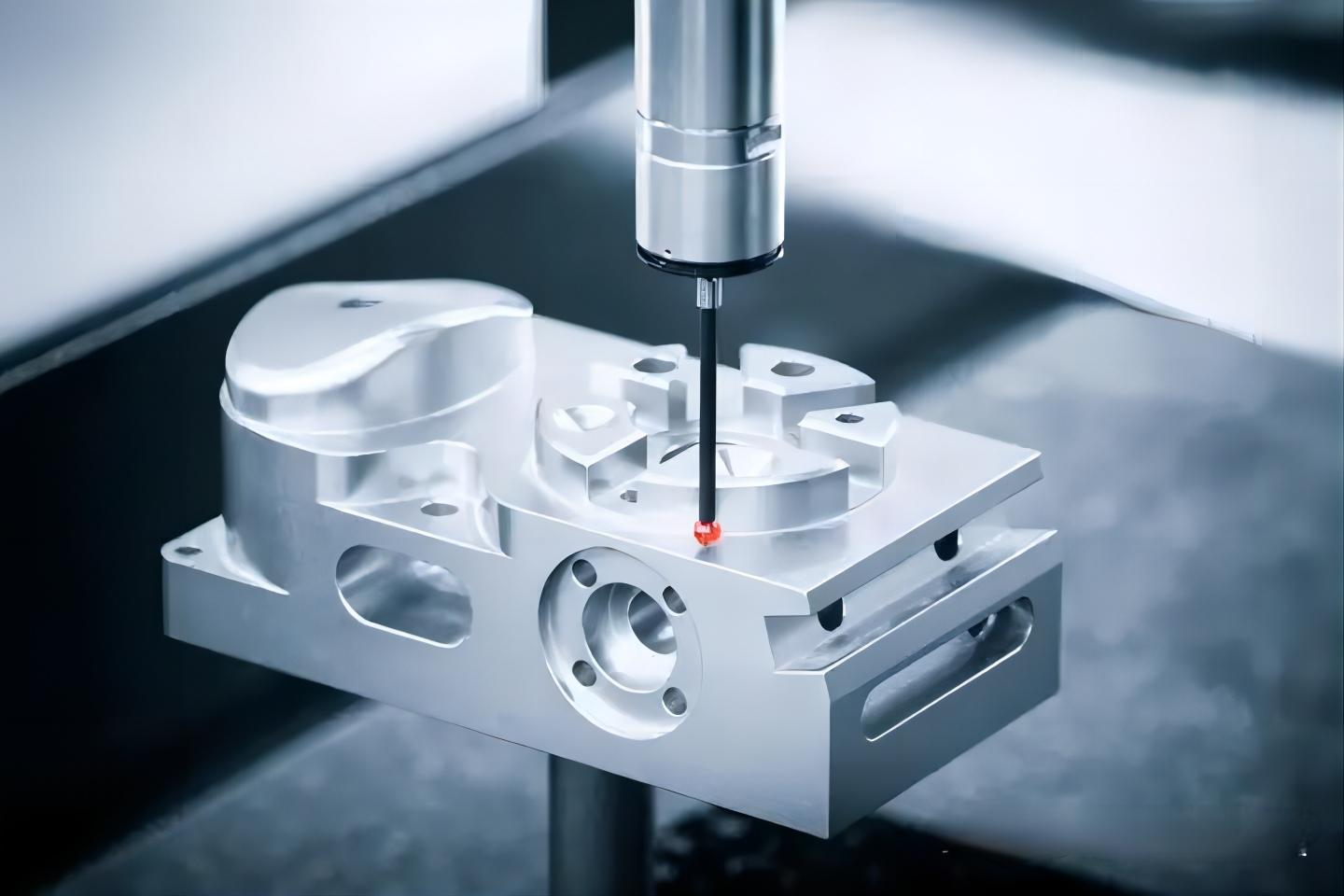

Inspection by in-process probing: An automated inspection performed during cnc machining service using programmed probes. These probes can verify key features and tolerances of the part, automatically monitor the process, and adjust the work coordinates and cutting tools accordingly.

Inspection by the Quality Control (QC) Department: An inspection phase performed by a team of quality control experts after cnc machining service is completed. QC experts use equipment such as height gauges, microscopes, 2D projectors, micrometers, and coordinate measuring machines (CMMs) to ensure that the parts meet customer requirements.