- Jun 27, 2024

What is CNC custom machining? CNC custom machining generally refers to small-batch CNC machining for production purposes that is performed according to customer-specific specifications and personalized needs, while meeting precise quality, on-time delivery, and cost-effectiveness and affordability.

CNC custom processing methods

In short, CNC custom processing is to manufacture parts that do not exist elsewhere with a clear purpose in CNC turning, CNC milling, automatic lathes and EDM, 5-axis CNC machining centers, etc.

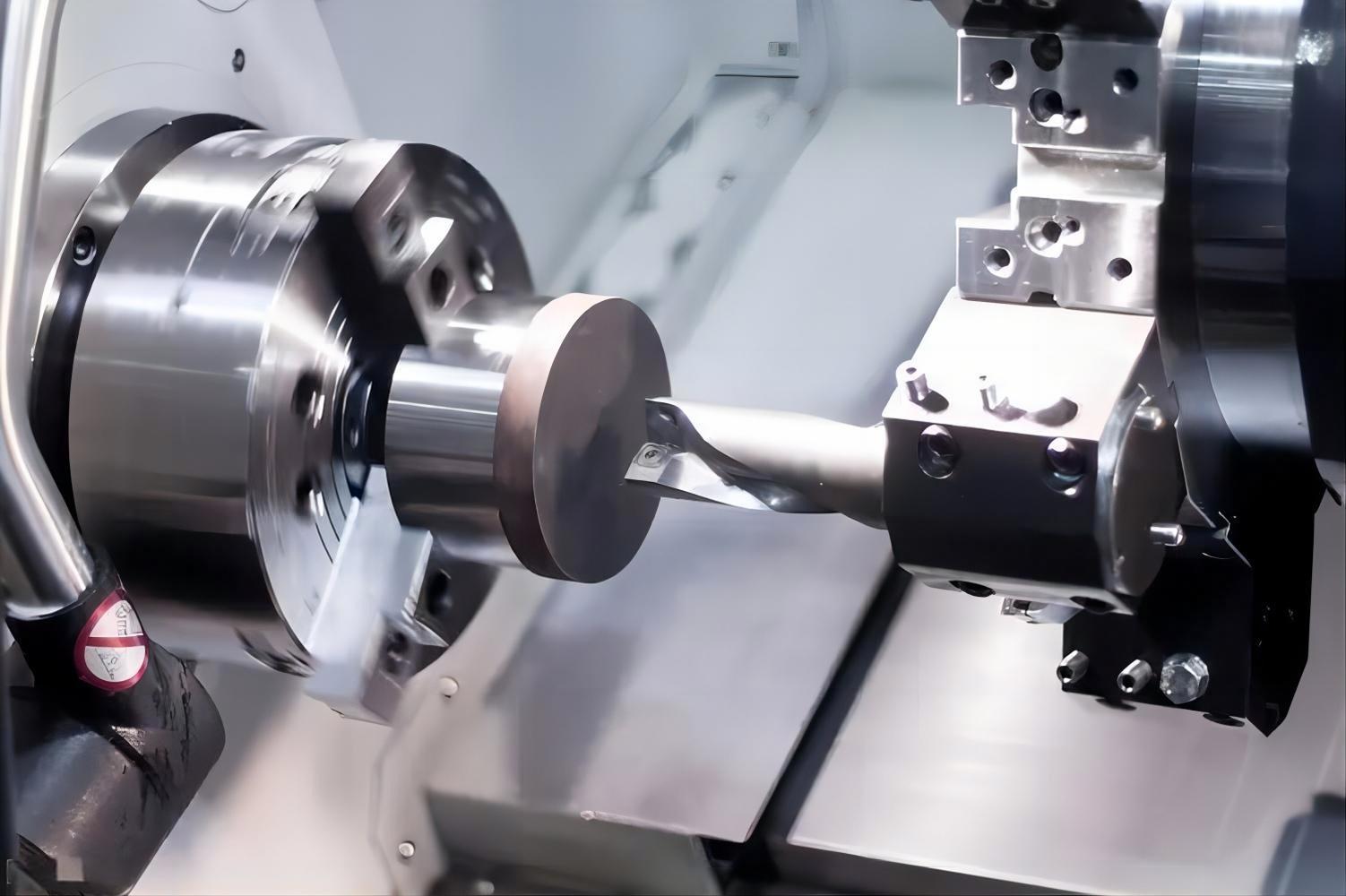

1. Turning

Lathe processing is part of mechanical processing. The turning tool is mainly used to turn the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves and other rotating or non-rotating workpieces with rotating surfaces. They are the most widely used type of machine tool processing in mechanical manufacturing and repair factories.

2. Milling

A common metal cold processing method, which is different from turning in that the tool rotates at high speed under the drive of the spindle in milling processing, while the workpiece being processed is relatively stationary.Turning is used to process rotating parts. The parts are clamped on the machine tool spindle through a three-claw chuck and rotated at high speed. Then the turning tool is used to cut along the generatrix of the rotating body to cut out the product appearance. The lathe can also process inner holes, threads, and biting, and the latter two are low-speed processing.

3. 3-axis processing

The 3-axis machine tool contains 3 linear axes, XYZ, and its structure is relatively simple. During processing, the direction of the tool axis will not change, the movement mode is limited, and the programming is relatively simple. The tool rotation axis can rotate, but it is only intermittent motion, and the direction of the cutting tool remains unchanged during the entire cutting path. The cutting state of the tool tip cannot be perfect in real time.

4. 5-axis processing

The 5-axis linkage machining center has the characteristics of high efficiency and high precision, and the workpiece can complete complex processing in one clamping. It can adapt to the processing of modern molds such as automotive parts and aircraft structural parts. There is a big difference between the five-axis machining center and the pentahedron machining center.

Many people don’t know this and mistake the pentahedron machining center for the five-axis machining center. The 5-axis machining center has 5 axes, x, y, z, a, c. The xyz and ac axes form a five-axis linkage machining, and are good at spatial curved surface machining, special-shaped machining, hollowing machining, drilling, oblique holes, bevel cutting, etc. The "pentahedron machining center" is similar to the three-axis machining center, except that it can do five faces at the same time, but it cannot do special-shaped machining, drilling oblique holes, cutting bevels, etc.On the surface, the 5-axis machine tool has two more rotation axes than the three-axis machine tool.

That is, in addition to the three linear axes XYZ, the 5-axis machine tool also includes two axes of the AC rotation axis that revolve around the three linear axes XYZ. Compared with the 3-axis, the 5-axis and 3-axis are mainly reflected in the machining capacity. The 5-axis machine tool can do the work of the 3-axis machine tool, but the 3-axis cannot do the work of the 5-axis. Due to the existence of two rotation axes, the 5-axis machine tool has stronger machining capabilities. In addition, the 5-axis improves the intermittent rotation of the 3-axis.

In addition, there are other processing methods, and different processing methods will be adopted for different processing requirements of customers. Because there are many reasons, there is usually a minimum order quantity because production will incur certain costs in the short term. Production in emergency situations, because the production time is shorter and there is rarely a minimum order quantity, it is necessary to quickly produce high-quality parts in the file to ensure fast and quality completion. During processing, some customers want to change a material to make this part, which will reduce production efficiency and time, but CNC processing does not require too many concerns, and materials can be quickly changed for production. Some parts require special materials for application, so they must be customized. Each new product part needs to be produced after customized sample testing, and the requirements are more stringent than other parts.