- Nov 12, 2024

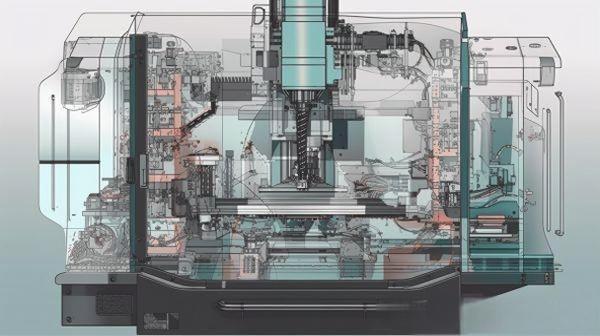

CNC (Computer Numerical Control) machining has revolutionized the manufacturing sector by enabling high precision, efficiency, and versatility in the production of parts and components. The automation of machine tools through computer programming has allowed for the precise control of various processes, such as milling, turning, drilling, and grinding. The ability to achieve complex shapes and tight tolerances has made CNC machining indispensable in many industries. This article explores the advantages of CNC machining and examines its wide range of applications across different sectors.

Advantages of CNC Machining

- High Precision and Accuracy

One of the most significant advantages of CNC machining is its ability to produce parts with high precision and accuracy. Traditional manual machining requires skilled labor to control the machines, which can introduce human error and inconsistency. In contrast, CNC machines follow pre-programmed instructions with exact coordinates, ensuring that each part is manufactured to the same exact specifications. The tight tolerances achieved in CNC machining are often in the range of microns, which is essential for industries that require highly precise components, such as aerospace and medical device manufacturing.

- Increased Efficiency and Productivity

CNC machines are highly efficient, operating continuously without the need for breaks. Unlike manual machining, where operators must set up the machine, make adjustments, and monitor progress, CNC machines can run autonomously, freeing up valuable time for manufacturers. This automation allows for faster production cycles and the ability to manufacture complex parts in less time. Additionally, CNC machining reduces material waste by optimizing tool paths and cutting strategies, contributing to cost savings and better resource management.

- Consistency and Reproducibility

CNC machining excels in producing parts with consistent quality. Once the programming is complete, the machine can replicate the same part thousands of times without any variation in the output. This is crucial for industries where batch production or mass manufacturing is common. Whether producing a single prototype or thousands of identical components, CNC machining service guarantees uniformity, which is essential for meeting industry standards and regulatory requirements.

- Flexibility and Complex Design Capabilities

CNC machines offer a level of flexibility that traditional machines cannot match. With a wide range of tools and attachments, CNC machines can perform various operations, such as milling, drilling, turning, and engraving, all within the same setup. This versatility allows manufacturers to produce parts with intricate geometries and complex features, such as undercuts, slots, and threads. Modern CNC machines can handle multi-axis movements, enabling the creation of even more sophisticated designs. Furthermore, the ability to make quick design adjustments through programming modifications allows cnc machining manufacturers to adapt to changing production requirements or client specifications.

- Reduced Labor Costs

CNC machining can significantly reduce labor costs by automating the production process. In manual machining, skilled labor is required to operate machines, monitor processes, and ensure quality control. CNC machines, on the other hand, require less human intervention. Once the programming is completed, machines can run automatically, minimizing the need for operators to constantly oversee the process. This reduction in human labor helps companies lower their overall operational costs while improving efficiency.

- High-Quality Surface Finishes

CNC machining can achieve high-quality surface finishes that meet or exceed the required standards. The precise control over cutting tools and movement allows for smoother finishes, which is critical in industries like aerospace, automotive, and medical manufacturing, where part aesthetics and functionality are paramount. Advanced CNC systems can incorporate post-processing techniques like polishing and deburring, further enhancing the surface finish and extending the life of the parts.

Application Industries of CNC Machining

- Aerospace Industry

The aerospace industry requires components that are lightweight, durable, and precise. CNC machining is crucial in this sector, where high tolerances and reliability are non-negotiable. CNC machines are used to produce critical components such as turbine blades, engine parts, landing gear, and structural elements of aircraft. Given the stringent safety standards, CNC machining ensures that every component meets the necessary specifications for strength and functionality. Moreover, the ability to work with materials such as titanium, aluminum, and other advanced alloys makes CNC machining ideal for the aerospace industry.

- Automotive Industry

The automotive sector benefits greatly from the precision and efficiency of CNC machining. Automotive manufacturers use CNC machines to produce a wide range of components, from engine blocks and cylinder heads to transmission parts and suspension systems. CNC machining is also used for the creation of custom parts for high-performance vehicles and prototypes. The automotive industry demands high-volume production of parts with minimal defects, and CNC machining provides the capability to achieve these standards consistently.

- Medical Device Manufacturing

The medical device industry relies heavily on CNC machining for producing parts that require both precision and reliability. Surgical instruments, implants, and medical equipment such as prosthetics are typically made using CNC technology. CNC machining allows manufacturers to produce complex, high-precision components that must adhere to strict health and safety regulations. The ability to machine materials like stainless steel, titanium, and medical-grade plastics ensures that the final products are not only functional but also biocompatible and safe for use in medical procedures.

- Electronics and Semiconductor Industries

CNC machining plays a vital role in the production of electronic components, such as housings, connectors, heat sinks, and circuit boards. The precision required to manufacture parts with tiny features and tight tolerances makes CNC machining an ideal choice for this industry. In the semiconductor sector, CNC machines are used to create precision components for chip manufacturing, packaging, and assembly processes. The high level of accuracy provided by CNC machines ensures that even the most delicate components are produced with minimal defects.

- Energy Sector

In the energy industry, particularly in the production of oil, gas, and renewable energy components, CNC machining is employed to create precision parts such as valves, turbines, pumps, and connectors. These components need to withstand extreme conditions, such as high pressures and temperatures, making the quality and precision achieved through CNC machining essential for their performance and longevity. CNC machines also support the production of custom parts for energy exploration and extraction equipment, helping companies maintain their equipment and meet operational demands.

- Tool and Die Industry

The tool and die industry involves the creation of molds, dies, and tools used in manufacturing processes like injection molding, stamping, and casting. CNC machining is invaluable in this industry because it allows for the precise creation of these critical tools. The ability to design complex geometries and ensure exact specifications for mold cavities and tool features ensures that the final products can be produced efficiently and accurately.

- Defense and Military Industries

The defense and military sectors require highly specialized components, many of which are produced using CNC machining. Components for weapons systems, radar equipment, vehicles, and military aircraft must meet stringent requirements for performance, durability, and safety. CNC machining’s ability to work with high-strength materials and produce complex designs makes it essential for these applications, where failure is not an option.

Conclusion:

CNC machining has revolutionized the manufacturing industry by offering numerous advantages, including high precision, increased productivity, flexibility, and reduced labor costs. Its applications span across a wide range of industries, from aerospace and automotive to medical devices and defense, providing manufacturers with the ability to produce high-quality, complex parts efficiently and cost-effectively. As technology advances, CNC machining will continue to play a pivotal role in shaping the future of modern manufacturing, driving innovation and growth across various sectors.