- Dec 04, 2024

CNC machining services and 3D printing are two of the most prominent manufacturing technologies today. Both offer unique advantages and limitations, making them suitable for different applications. In this article, we will compare the two technologies to help you decide which is best for your needs, particularly when considering custom CNC services, CNC machining services, or CNC manufacturing services.

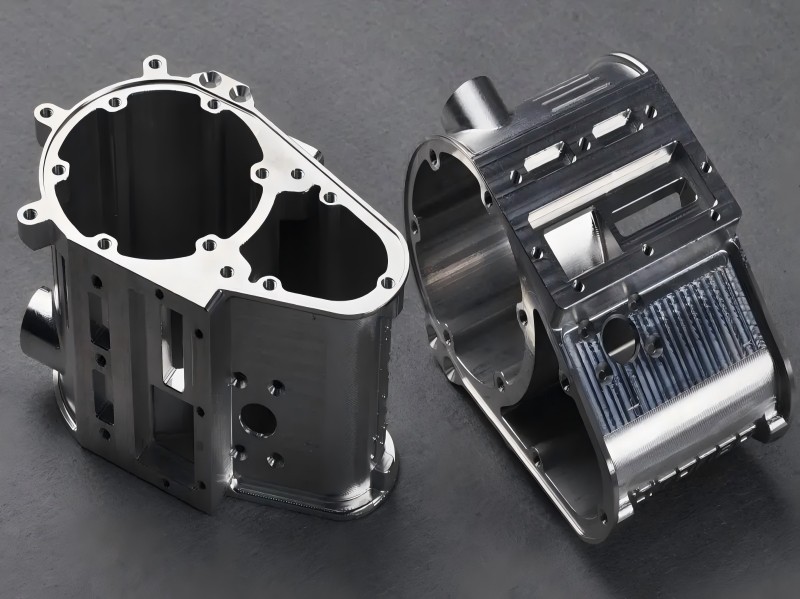

What Are CNC Machining Services?

CNC machining services involve the use of computer-controlled machines to precisely remove material from a solid block (workpiece) to create the desired shape. These services are ideal for high-precision parts and are commonly used in industries like aerospace, automotive, and medical.

Key benefits of CNC machining include:

High precision and accuracy

Wide range of materials (metals, plastics, composites)

Scalability for large production runs

What Is 3D Printing?

3D printing, or additive manufacturing, builds objects layer by layer from a digital file. This process is highly versatile and is often used for prototyping, small-batch production, or creating complex geometries that are difficult to achieve with traditional methods.

Key benefits of 3D printing include:

Design flexibility

Low material waste

Rapid prototyping

CNC Machining Services vs. 3D Printing

Here’s a detailed comparison of these two technologies based on critical factors:

Material Options

CNC Machining Services: Works with a wide range of materials, including metals (aluminum, stainless steel, titanium) and plastics. It’s the preferred choice for durable and functional components.

3D Printing: Best suited for plastics and some metals but often lacks the material strength offered by CNC machining. Advanced 3D printing methods like SLS or DMLS have improved metal options but are typically costlier.

Precision and Tolerances

CNC Machining Services: Renowned for its high precision, with tolerances as tight as ±0.001 inches. It’s ideal for intricate parts requiring strict dimensional accuracy.

3D Printing: While improving, most 3D printers cannot achieve the precision of CNC machines. Surface finishes also often require post-processing.

Production Speed

CNC Machining Services: Faster for large production runs but requires setup time for custom CNC services.

3D Printing: Faster for prototyping and small batches as it eliminates the need for tooling.

Cost Efficiency

CNC Machining Services: More cost-effective for large volumes due to economies of scale. However, it may involve higher initial setup costs.

3D Printing: More economical for low-volume production or complex designs but can be expensive for high-volume manufacturing.

Application Suitability

CNC Machining Services: Best for end-use parts, high-performance components, and large-scale production.

3D Printing: Ideal for creative designs, rapid prototyping, and parts with intricate internal geometries.

Which Should You Choose?

Choose CNC Machining Services if you need high precision, durability, or large-scale production. Industries that require custom CNC services often benefit from the repeatability and reliability of CNC manufacturing.

Choose 3D Printing if you need to prototype quickly, create highly complex designs, or work with low production volumes.

Conclusion:

While both CNC machining services and 3D printing have their place in modern manufacturing, the choice depends on your specific requirements. For high-quality, durable, and precision-driven components, custom CNC services and CNC manufacturing services are unmatched. On the other hand, 3D printing excels in creativity, flexibility, and quick turnaround for prototypes. By understanding the strengths and limitations of each technology, you can make an informed decision to achieve your project’s goals effectively. For reliable and precision-driven CNC machining services, contact us today to explore custom solutions tailored to your manufacturing needs!