- Dec 10, 2024

When it comes to manufacturing precision parts, the debate often arises between traditional machining methods and modern custom CNC machining services. With the rapid evolution of technology, CNC machining has gained significant attention for its accuracy, efficiency, and versatility. Let’s explore why choosing a CNC machining service is often the superior option, particularly for rapid prototypes and complex designs.

What Is Custom CNC Machining?

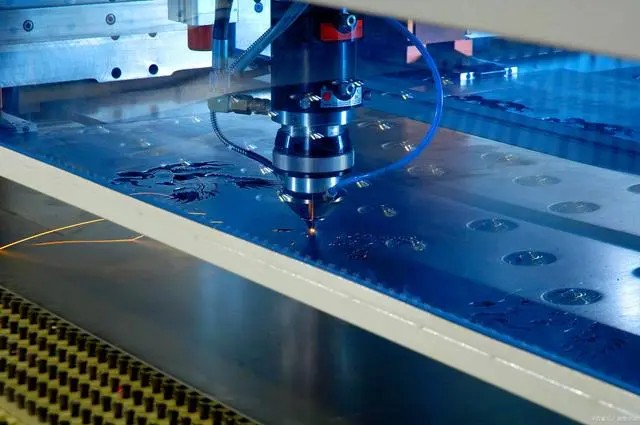

Custom CNC machining services utilize computer-controlled machines to produce high-precision parts from various materials such as metals, plastics, and composites. Unlike traditional machining, which relies heavily on manual intervention, CNC (Computer Numerical Control) systems ensure consistent and repeatable results, making them ideal for projects requiring tight tolerances.

Advantages of Custom CNC Machining Services

Precision and Accuracy

CNC machining delivers unparalleled precision, with tolerances often within ±0.001 inches. This level of accuracy is crucial for industries such as aerospace, automotive, and medical, where even minor deviations can lead to critical failures.Consistency in Production

Once a design is programmed into the CNC system, the machine can replicate identical parts without deviations. This consistency is invaluable for projects requiring mass production or repeatable results over multiple production cycles.Efficiency and Speed

CNC machines operate at high speeds and can perform complex operations in a fraction of the time compared to traditional methods. For CNC machining services for rapid prototypes, this efficiency means faster turnaround times, enabling businesses to accelerate their product development cycles.Complex Design Capabilities

Custom CNC machining allows for intricate geometries and complex designs that traditional methods might struggle to achieve. Multi-axis CNC machines can create components with detailed contours, undercuts, and other challenging features.Versatility with Materials

CNC machining can handle a wide range of materials, including aluminum, stainless steel, titanium, and various plastics. This versatility makes it a go-to solution for diverse industries.Cost-Effectiveness for Prototyping

While initial setup costs may be higher, CNC machining services for prototypes reduce material waste and minimize errors, ultimately lowering overall costs for small production runs.Scalability

Whether you need a single prototype or a full production run, CNC machining scales seamlessly. This adaptability ensures businesses can meet varying demands without compromising quality.

Traditional Methods vs. CNC Machining Services

| Feature | Traditional Machining | CNC Machining |

|---|---|---|

| Precision | Limited, manual-dependent | Extremely high, computer-controlled |

| Speed | Slower, labor-intensive | Fast, automated |

| Consistency | Variations due to human error | Perfect repeatability |

| Complexity | Limited to simpler geometries | Handles intricate designs |

| Setup Costs | Lower initial costs | Higher initial programming costs |

| Material Waste | More waste due to manual errors | Optimized material usage |

The comparison highlights the clear advantages of custom CNC machining services over traditional methods, particularly for precision manufacturing and complex designs.

Applications of CNC Machining Services

Prototyping and Rapid Prototypes

For companies developing new products, CNC machining services for rapid prototypes offer quick and precise production of functional models, allowing for thorough testing before full-scale production.Aerospace Components

Aerospace parts require high precision and durability, making CNC machining the preferred choice for critical components like turbine blades and engine parts.Automotive Industry

From prototypes to production parts, CNC machining supports the automotive sector by creating custom components with excellent mechanical properties.Medical Equipment

CNC machining plays a vital role in producing surgical instruments, implants, and other medical devices requiring exceptional accuracy.Industrial Machinery

Custom CNC machining ensures durable and reliable parts for industrial applications, including gears, housings, and precision tools.

How to Choose the Right CNC Machining Service Provider

To maximize the benefits of CNC machining, partnering with a reliable service provider is crucial. Consider the following factors:

- Expertise: Ensure the provider specializes in custom CNC machining services tailored to your industry.

- Equipment: Look for a company with advanced, multi-axis CNC machines.

- Material Options: A good provider offers a variety of material choices to meet your specific needs.

- Turnaround Time: For time-sensitive projects, select a service known for rapid prototyping capabilities.

- Quality Assurance: Ensure the provider adheres to strict quality control measures for consistent results.

Conclusion:

Choosing a custom CNC machining service over traditional methods is a strategic decision that offers numerous advantages, from unmatched precision to scalability and cost-efficiency. Whether you need prototypes or full-scale production, CNC machining delivers consistent, high-quality results tailored to your project’s requirements. For businesses seeking reliable and efficient solutions, investing in CNC technology is a step toward innovation and success.By partnering with a trusted CNC machining service provider, you ensure your projects meet the highest standards of quality and performance. As industries continue to demand greater precision and complexity, CNC machining remains an indispensable tool for modern manufacturing.