- Dec 10, 2024

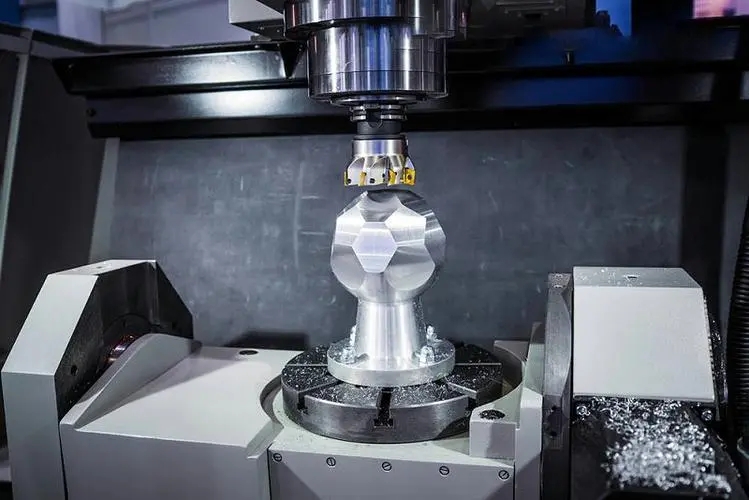

In today’s manufacturing landscape, the demand for precision and efficiency drives the adoption of advanced technologies. Custom CNC machining services meet these demands by providing tailored solutions for diverse industries. From crafting prototypes to producing complex parts, CNC machining services offer unmatched precision, scalability, and versatility.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software automates machinery operations. This results in precise and consistent production of parts, making it an ideal choice for industries requiring high accuracy.A custom CNC machining service focuses on producing parts that meet specific client requirements, whether for prototyping or full-scale production.

Key Benefits of CNC Machining Services

| Benefit | Description |

|---|---|

| High Precision | Achieves tight tolerances and intricate designs with exceptional accuracy. |

| Material Versatility | Compatible with metals (aluminum, steel) and plastics (ABS, PEEK, etc.). |

| Rapid Prototyping | Delivers functional prototypes quickly to accelerate product development. |

| Cost-Effective | Reduces material waste and saves costs in the long term. |

| Scalability | Supports both small production runs and large-scale manufacturing. |

Applications of CNC Machining Services

1. Prototyping

CNC machining services for prototypes help companies test designs and identify potential issues before mass production.

2. Aerospace and Defense

These industries require high-precision custom parts for aircraft components and military-grade equipment.

3. Medical Devices

CNC machining plays a vital role in manufacturing prosthetics, surgical instruments, and medical devices with strict quality standards.

4. Automotive

Custom CNC machining is used for creating engine parts, transmission systems, and other high-performance components.

5. Consumer Electronics

From casings to connectors, CNC machining ensures reliable and aesthetically pleasing components.

Why Choose CNC Machining Services for Rapid Prototypes?

CNC machining is ideal for rapid prototypes due to its speed, accuracy, and compatibility with various materials. Unlike 3D printing, CNC machining creates prototypes with superior strength and finish.

| Comparison | CNC Machining | 3D Printing |

|---|---|---|

| Material Options | Wide range (metals and plastics) | Limited, mainly plastics and resins |

| Precision | High | Moderate |

| Surface Finish | Excellent | May require post-processing |

| Durability | Stronger prototypes | Suitable for concept models |

For businesses looking to develop robust, functional prototypes quickly, CNC machining services are the go-to choice.

How to Choose the Right Custom CNC Machining Service Provider

Selecting a reliable provider ensures the success of your project. Key factors to consider include:

Expertise and Experience

Look for providers with extensive industry experience and proven technical expertise.Advanced Equipment

Ensure the service provider uses state-of-the-art CNC machines to meet precision requirements.Material Selection

Verify that the provider offers a wide range of material options for your specific needs.Customer Support

A responsive and knowledgeable team can address your concerns efficiently.On-Time Delivery

Choose a provider known for delivering projects on time without compromising quality.

Oakon: Your Trusted CNC Machining Partner

At Oakon, we specialize in providing custom CNC machining services that meet diverse industry requirements. From CNC machining services for rapid prototypes to large-scale manufacturing, we ensure precision, quality, and efficiency at every step.Our commitment to excellence includes advanced machinery, skilled professionals, and a client-focused approach. Whether you need prototypes or mass production, Oakon is equipped to deliver outstanding results tailored to your needs.CNC machining services are indispensable for industries that require precision, efficiency, and adaptability. By leveraging custom CNC machining services, businesses can achieve superior-quality parts while optimizing costs and time. Whether for prototypes or full-scale production, partnering with a trusted provider like Oakon ensures your success in the competitive manufacturing landscape.

FAQ

Q1: What industries benefit most from CNC machining services?

A: Industries such as aerospace, automotive, medical, and electronics heavily rely on CNC machining for precision components.

Q2: Why is CNC machining preferred for rapid prototypes?

A: CNC machining provides accurate, durable, and production-ready prototypes, making it a superior choice compared to other methods.

Q3: What materials can CNC machining handle?

A: CNC machining works with a wide range of materials, including metals like aluminum and plastics like ABS.

Q4: How does CNC machining reduce costs in the long run?

A: By minimizing material waste and ensuring precise production, CNC machining lowers costs associated with errors and inefficiencies.

Q5: What sets Oakon apart in CNC machining services?

A: Oakon combines advanced technology, skilled professionals, and a client-focused approach to deliver customized solutions with unparalleled quality.