- Dec 18, 2024

Choosing the right provider for CNC machining prototype customization is crucial for ensuring high-quality results and timely project completion. A reliable provider will help you bring your designs to life with precision and efficiency. In this article, we’ll guide you through the key factors to consider when selecting a provider, ensuring your investment delivers the desired outcomes.

Understanding CNC Machining Prototype Customization

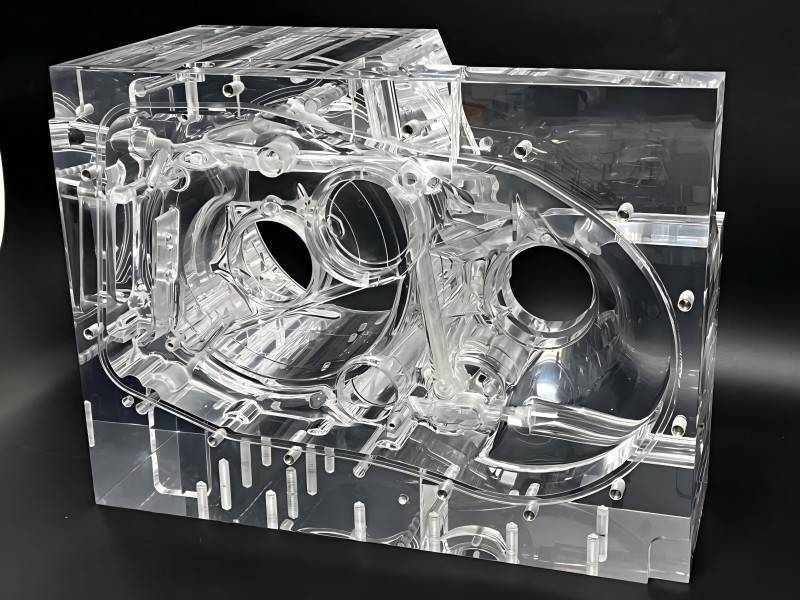

CNC machining prototype customization involves tailoring prototypes to specific requirements using advanced CNC machining technologies. This process offers precision, scalability, and flexibility, making it ideal for industries like aerospace, automotive, and medical device manufacturing. Providers also often combine CNC machining with other methods, such as custom 3D printed prototypes and rapid prototype customization, to meet diverse needs.

Key Factors to Consider When Selecting a Provider

When evaluating providers, focus on the following factors:

| Criteria | What to Look For |

|---|---|

| Experience and Expertise | A proven track record in CNC machining prototype customization for various industries. |

| Equipment and Technology | Advanced CNC machines and complementary technologies like 3D printing and injection molding. |

| Material Options | A wide range of materials, including metals, plastics, and composites, to match your project needs. |

| Customization Capabilities | Ability to handle complex designs, tight tolerances, and tailored finishes. |

| Turnaround Time | Efficient processes for rapid prototype customization without compromising quality. |

| Cost-Effectiveness | Competitive pricing with clear quotes and no hidden fees. |

| Communication and Support | Transparent updates, clear communication, and post-project support. |

Why Expertise Matters

Providers with expertise in CNC machining prototype customization and prototype manufacturing customization are better equipped to handle challenges. Their knowledge ensures your designs are executed accurately, saving time and costs while maintaining high quality.

The Role of Equipment and Technology

The best providers use state-of-the-art CNC machines and tools. Look for a provider who integrates CNC machining with technologies like custom 3D printed prototypes. This hybrid approach can accommodate complex projects and improve design iterations.

Material Selection and Its Importance

Choosing the right material is crucial for prototype functionality and performance. A reliable provider will offer diverse material options and expert guidance on selecting the best materials for your application, whether it’s for strength, heat resistance, or lightweight properties.

Balancing Cost and Quality

Cost is an important factor, but it shouldn’t come at the expense of quality. A trusted provider will deliver value through competitive pricing, transparency, and a focus on producing prototypes that meet all specifications.

Conclusion:

Selecting the right provider for CNC machining prototype customization requires careful evaluation of their expertise, technology, materials, and customer support. By partnering with a provider skilled in rapid prototype customization and prototype manufacturing customization, you can ensure your prototypes are produced efficiently, accurately, and to the highest standard.Investing time in selecting a reliable provider not only enhances your prototype’s quality but also accelerates the product development process, giving you a competitive edge in the market