- Dec 18, 2024

Low-volume prototype customization is a key process in product development, providing tailored solutions for industries ranging from electronics to automotive. By focusing on small production runs, it enables businesses to validate designs, test functionality, and address market demands efficiently. This article explores the benefits of low-volume prototype customization and its role in modern manufacturing.

1. What is Low-Volume Prototype Customization?

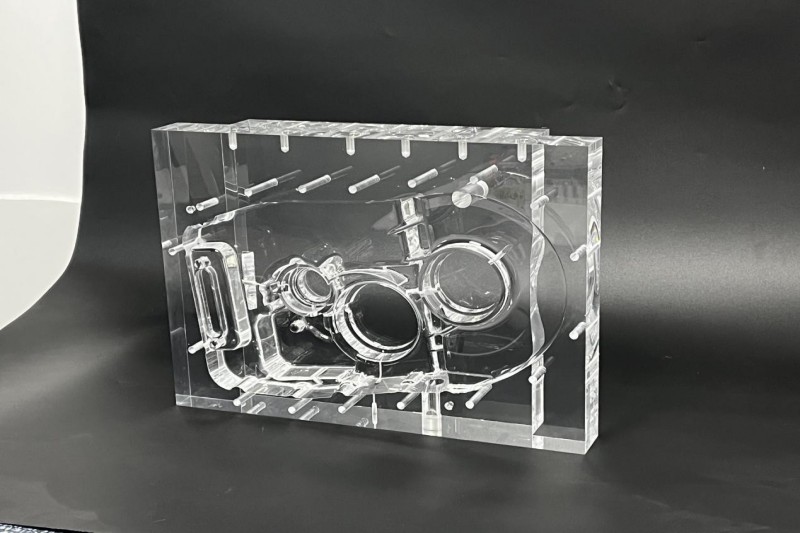

Low-volume prototype customization involves producing a limited number of prototypes tailored to specific project requirements. It is particularly beneficial for companies looking for high-precision prototype customization and fast prototype customization services, ensuring the product meets design and functionality goals before full-scale production.

2. Benefits of Low-Volume Prototype Customization

| Benefit | Description |

|---|---|

| Cost-Effective Production | Reduces upfront costs by limiting production to small batches, making it ideal for startups and SMEs. |

| Faster Time-to-Market | Speeds up the product development cycle by providing quick iterations and faster testing phases. |

| Design Flexibility | Allows for rapid adjustments and modifications to improve the design based on feedback. |

| Risk Mitigation | Identifies potential design or functionality issues before committing to large-scale production. |

| High Precision | Ensures detailed and accurate prototypes that reflect final production quality standards. |

| Custom Material Options | Supports a wide range of materials tailored to specific industry or functional requirements. |

| Market Testing Capability | Enables testing of products in real-world scenarios to gather consumer or client feedback. |

3. Key Features of High-Precision Prototype Customization

High-precision prototype customization is an integral part of low-volume production. This approach guarantees tight tolerances, detailed finishes, and functional accuracy, making it suitable for industries such as aerospace, medical devices, and consumer electronics. By leveraging advanced CNC machining and 3D printing technologies, manufacturers can deliver prototypes that meet exact specifications.

4. How Fast Prototype Customization Services Enhance Efficiency

Fast prototype customization services are designed to meet tight project deadlines without sacrificing quality. Providers equipped with automated processes and state-of-the-art machinery can accelerate production, enabling businesses to iterate and validate designs in record time. This capability is essential for staying competitive in fast-moving industries.

5. Selecting the Right Partner for Low-Volume Prototype Customization

Choosing a reliable provider is critical to unlocking the full benefits of low-volume prototype customization. Evaluate potential partners based on:

| Criteria | What to Look For |

|---|---|

| Expertise | Proven experience in high-precision and fast prototype customization services. |

| Technology | Access to advanced CNC machining, 3D printing, and other fabrication technologies. |

| Material Options | Wide range of material choices to meet specific project needs. |

| Turnaround Time | Demonstrated ability to meet deadlines for fast prototype delivery. |

| Customer Support | Clear communication, transparent pricing, and post-production support. |

Low-volume prototype customization offers numerous benefits, including cost efficiency, faster development cycles, and enhanced design flexibility. By combining high-precision customization with fast services, businesses can refine their products, mitigate risks, and deliver superior solutions to the market. Partnering with an experienced provider equipped with cutting-edge technologies ensures you receive high-quality prototypes tailored to your needs. Whether you’re a startup validating a new idea or an established company testing product iterations, low-volume prototype customization is a powerful tool in achieving your goals.