- Dec 25, 2024

Prototyping and 3D printing services are rapidly becoming the go-to solutions for companies looking to accelerate product design and development. From the ability to create custom 3D models for printing to offering rapid iteration and testing, 3D printing for product design brings countless benefits to businesses in various industries. In this article, we will explore why you should consider these services and how they can enhance your product development process.

1. Speed and Efficiency in Product Development

One of the most compelling reasons to use prototyping and 3D printing services is the speed they offer. Traditional prototyping methods often require lengthy lead times, as they involve expensive tooling, molds, or manual labor. In contrast, 3D printing allows companies to design and produce prototypes much more quickly, making it easier to test new concepts and get products to market faster.

With 3D printing for product design, businesses can:

- Reduce lead times by skipping the traditional molding and tooling process.

- Quickly iterate designs and create multiple versions of a prototype to assess different configurations.

- Improve product development timelines, ultimately reducing time-to-market for new products.

For businesses that need to move quickly and efficiently, prototyping and 3D printing services offer a clear advantage over traditional methods.

2. Cost-Effective Prototyping and Design Customization

Traditional prototyping often involves significant upfront costs, especially when creating custom molds or tooling. With prototyping and 3D printing services, companies can drastically reduce these expenses. 3D printing does not require complex tooling setups, and parts are produced layer by layer, which means less material waste and lower overall production costs.

Additionally, custom 3D models for printing enable designers to create highly specific parts or features that may not be possible with traditional methods. This flexibility in design is particularly useful for industries where customization is a necessity, such as:

- Automotive: Customizing parts to fit unique specifications.

- Healthcare: Designing medical devices that cater to individual patient needs.

- Consumer Electronics: Developing prototypes with specific features or components tailored to user preferences.

By leveraging prototyping and 3D printing services, companies can produce highly specialized, customized prototypes at a fraction of the cost of traditional methods.

3. Flexibility in Design and Innovation

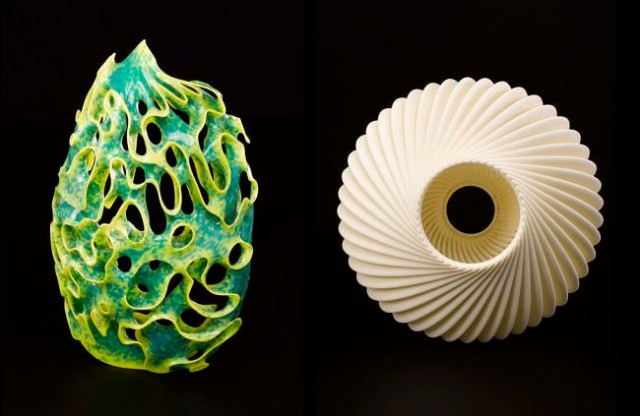

Traditional prototyping can often limit a designer's creativity due to the constraints of manufacturing processes. However, with 3D printing for product design, designers have the freedom to experiment with more intricate designs, including complex geometries and lightweight structures that would otherwise be impossible or cost-prohibitive to create using conventional methods.

Some key advantages include:

- Complex Geometries: 3D printing allows for the creation of prototypes with intricate internal features, hollow spaces, and complex designs that would otherwise require additional parts or manual assembly.

- Multiple Materials: Depending on the requirements, designers can use a wide range of materials, from plastics and resins to metals, giving them the flexibility to create functional prototypes that can withstand real-world conditions.

- Iterative Design: Designers can quickly test out different design variations, making iterative improvements based on performance and feedback.

With prototyping and 3D printing services, the limits of creativity are greatly expanded, enabling businesses to innovate in ways that would be difficult with traditional manufacturing.

4. Accurate and Reliable Testing

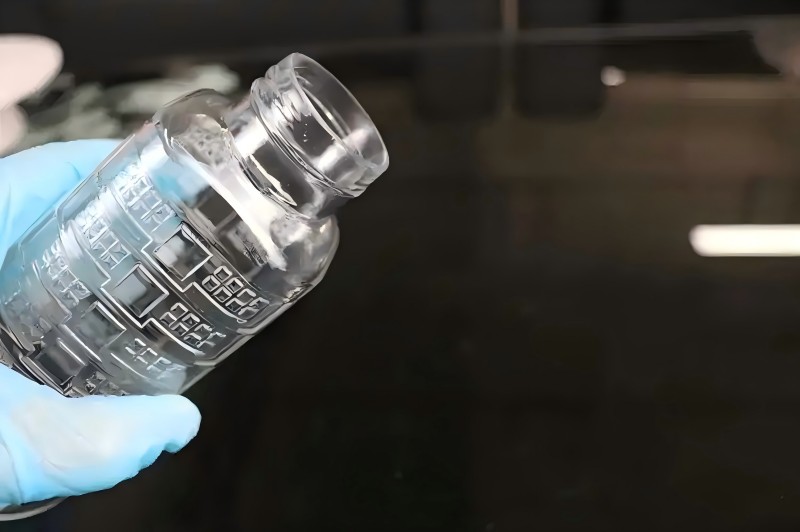

Testing is a crucial part of the prototyping process, as it helps businesses identify design flaws early and make necessary adjustments before moving to full-scale production. 3D printing for product design enables more reliable and accurate testing by providing realistic prototypes that are very close to the final product.

Prototyping and 3D printing services allow companies to:

- Test functionality: Prototypes made using custom 3D models for printing can mimic the final product’s form and function, helping companies understand how the design will perform under real-world conditions.

- Identify design flaws: Early-stage testing through prototypes allows teams to spot issues with the design or functionality before moving to expensive production stages.

- Refine the product: With each iteration, designers can refine their product, improving its usability, aesthetics, and performance.

This level of accurate testing helps minimize the risk of costly errors or redesigns later in the production process.

5. Sustainability and Material Efficiency

One of the growing concerns in manufacturing is sustainability, and prototyping and 3D printing services offer a more environmentally friendly solution. Traditional manufacturing processes often involve significant material waste, especially when using molds or cutting away excess material. 3D printing, however, is an additive process, meaning materials are used only where necessary, reducing waste significantly.

Sustainability in 3D printing is further enhanced by the following:

- Material Recycling: Many 3D printing services use recyclable materials, allowing for more sustainable production processes.

- On-Demand Production: 3D printing produces prototypes only when needed, eliminating the need for large inventories or overproduction.

- Lower Carbon Footprint: Because 3D printing is often more localized, the shipping and transportation associated with traditional manufacturing are minimized, reducing carbon emissions.

For businesses committed to sustainability, 3D printing for product design offers a cleaner, greener alternative.

6. Why Choose Oakon for Prototyping and 3D Printing Services?

At Oakon, we specialize in providing high-quality prototyping and 3D printing services designed to meet the unique needs of your business. Whether you require custom 3D models for printing, complex 3D printing for product design, or rapid prototyping solutions, our team is here to help you bring your ideas to life quickly and cost-effectively.

Some reasons to choose Oakon include:

- Expertise: Our team has extensive experience in 3D printing for product design and prototyping, ensuring that your project is handled with the utmost precision.

- Advanced Technology: We use cutting-edge 3D printing technologies and materials to create accurate and durable prototypes.

- Customization: We offer highly customized 3D models for printing, tailored to your specific design requirements.

- Sustainability: We are committed to using eco-friendly materials and sustainable practices in our prototyping and 3D printing services.

Prototyping and 3D printing services are revolutionizing the way businesses approach product development. With the ability to create custom 3D models for printing, test designs quickly, and reduce costs, 3D printing for product design offers unparalleled flexibility, speed, and accuracy. Whether you're in need of rapid prototyping or looking to create complex product designs, leveraging these services will help you stay ahead of the competition. Partnering with a trusted provider like Oakon ensures that your products are developed with precision, efficiency, and sustainability.