- Jan 07, 2025

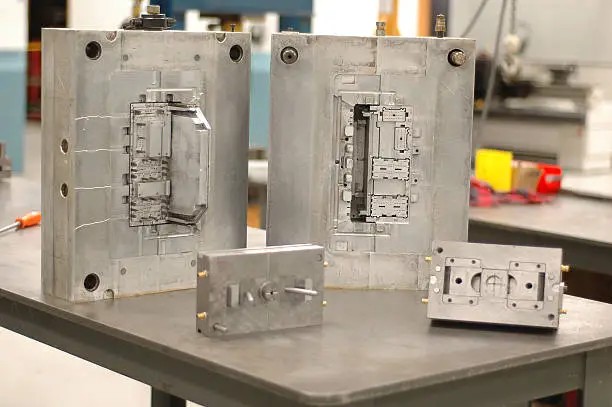

One powerful tool that helps achieve this goal is custom mold prototyping. Whether you're developing a new product or refining an existing one, custom mold prototyping offers a range of benefits that can save both time and money in the product development lifecycle. In this article, we’ll explore how custom mold prototyping, rapid mold manufacturing, and 3D printed mold prototypes can streamline production and lead to more efficient outcomes.

1. Faster Product Development with Custom Mold Prototyping

Traditional mold making is often a time-consuming process that can involve several steps, including design, material selection, and tooling. However, with custom mold prototyping, the process is significantly faster. This rapid approach to prototyping uses advanced technologies, such as 3D printed mold prototypes, to quickly create functional models that can be tested and refined before full-scale production.

With custom mold prototyping, you can quickly iterate on designs, ensuring that the final mold is optimized for both performance and cost. This reduces the overall timeline, allowing products to reach the market much faster.

Benefits:

- Reduced lead times

- Faster design iterations

- Quick feedback on design functionality

2. Cost Savings with Rapid Mold Manufacturing

One of the most significant advantages of rapid mold manufacturing is the reduction in costs. Traditional mold manufacturing often requires expensive tooling and extensive setup times, both of which can add to production expenses. By using rapid mold manufacturing techniques, businesses can drastically cut down on these costs.

For instance, 3D printed mold prototypes allow for the rapid creation of molds without the need for expensive tooling. These molds can be used for low-volume production runs or as initial testing tools, making them an affordable alternative to traditional metal molds, which can be costly and time-consuming to produce.

Benefits:

- Lower tooling and setup costs

- Reduced need for high-volume production runs

- More affordable prototypes for initial testing

3. Improved Accuracy and Reduced Errors

Custom molds are often complex and require a high degree of precision. Traditional prototyping methods can sometimes introduce human error, leading to costly rework or even delays in production. With custom mold prototyping, precision is greatly improved.

Modern technologies like 3D printing can create prototypes with high accuracy and fine detail, ensuring that the final mold matches the design specifications perfectly. This reduces the chances of errors and the need for costly revisions, which saves both time and money.

Benefits:

- Increased precision

- Fewer errors and revisions

- Improved final product quality

4. Minimizing Waste in Prototype Mold Manufacturing

Traditional mold making often involves substantial waste in terms of both materials and time. Prototype mold manufacturing services help mitigate this by using less material in the early stages of development, especially when creating 3D printed mold prototypes. Since 3D printed mold prototypes are additive, they only use the material needed for the mold, reducing waste compared to subtractive methods.

Additionally, rapid mold manufacturing techniques allow for faster testing and iteration, meaning fewer resources are tied up in failed prototypes. With these methods, companies can more effectively control their production costs while ensuring that the molds they do produce are exactly what they need.

Benefits:

- Less material waste

- Lower resource usage

- Efficient use of time and materials

5. Low-Volume Production and Quick Testing

For businesses looking to produce small batches of products, custom mold prototyping offers a unique advantage. Rapid mold manufacturing and 3D printed mold prototypes allow companies to produce small quantities of molds quickly and at a low cost. This is especially useful for testing products in the market or for running short production trials before committing to a larger-scale production.

Prototype mold manufacturing services also provide the flexibility to create prototypes that can be tested in real-world conditions. This enables businesses to identify and resolve potential issues early in the process, saving both time and money in the long run by preventing larger production issues.

Benefits:

- Cost-effective low-volume production

- Efficient testing before full-scale production

- Flexibility to refine designs quickly

6. Faster Time to Market

In today’s competitive market, getting products to market faster can be the key to success. With custom mold prototyping, the entire product development cycle is accelerated. By eliminating long tooling lead times and reducing the number of iterations required to finalize a mold, companies can produce functional prototypes and move into full-scale manufacturing much quicker.

The ability to use rapid mold manufacturing and 3D printed mold prototypes allows for quicker production of trial runs and testing, speeding up the process from design to market launch. This can be a huge advantage in industries where speed-to-market is critical.

Benefits:

- Quicker product launches

- More opportunities for market testing

- Reduced development time

Custom mold prototyping offers a wide range of benefits that can save both time and money during the product development process. By leveraging techniques like rapid mold manufacturing, 3D printed mold prototypes, and prototype mold manufacturing services, businesses can reduce production costs, improve accuracy, minimize waste, and shorten development timelines.

With these advancements, companies can not only enhance their production processes but also accelerate their path to market, making custom mold prototyping an invaluable tool in today’s manufacturing industry. Whether you're looking to create custom molds for small batches or testing new designs, rapid prototyping services offer the speed and cost-effectiveness you need to stay ahead of the competition.