- Jan 14, 2025

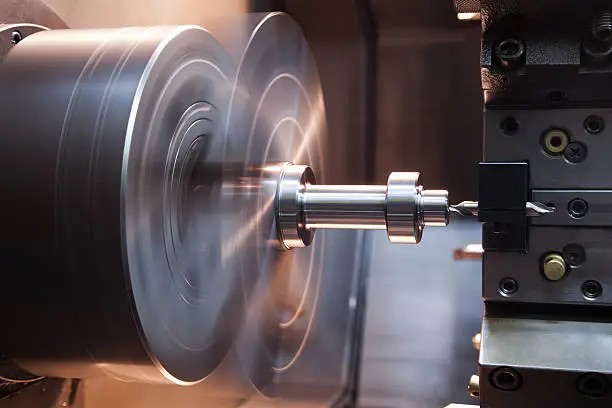

In today’s manufacturing landscape, achieving precision and efficiency is crucial for producing high-quality parts. CNC machining services have emerged as a reliable solution for industries requiring custom components. From prototyping to mass production, CNC machining ensures accuracy, repeatability, and cost-effectiveness.

This article explores why custom CNC services are the top choice for creating precision parts and how they cater to industries such as automotive, aerospace, and medical technology.

What Are CNC Machining Services?

CNC (Computer Numerical Control) machining services use automated tools and computerized systems to manufacture parts with exceptional precision. By following pre-programmed designs, CNC machines can cut, mill, drill, and shape a wide range of materials, including metals, plastics, and composites.

Key Features of CNC Machining:

| Feature | Benefit |

|---|---|

| High Precision | Delivers parts with tight tolerances, typically within ±0.01mm. |

| Versatility | Works with diverse materials like aluminum, steel, titanium, and more. |

| Customization Capability | Ideal for custom prototypes and low-to-high volume production. |

Why Choose CNC Machining for Precision Parts?

1. Exceptional Accuracy

CNC machines can create parts with unparalleled precision, meeting even the most stringent industry standards. This is especially important for applications where precision is critical, such as aerospace components and medical implants.

2. Efficiency and Speed

Modern CNC machining services are designed to optimize production time while maintaining quality. Once the design is programmed, the machine can produce parts quickly, reducing lead times for custom projects.

3. Flexibility for Custom Prototypes

For businesses developing new products, custom prototypes are essential. CNC machining allows for rapid prototyping, enabling manufacturers to test designs and make modifications before mass production. This flexibility ensures that products meet functional and aesthetic requirements.

4. Material Variety

CNC machines are compatible with a broad range of materials, making them suitable for industries with diverse needs. Whether you require lightweight plastics or high-strength metals, CNC machining can handle it all.

How CNC Machining Services Benefit Different Industries

| Industry | Applications |

|---|---|

| Automotive | Engine components, custom parts, prototypes |

| Aerospace | High-precision turbine blades, structural components |

| Medical | Surgical instruments, implants, custom medical devices |

| Electronics | Housing for devices, connectors, precision fittings |

Advantages of Custom CNC Services

1. Scalability

From single prototypes to large-scale production, custom CNC services can accommodate projects of any size. This scalability is particularly valuable for startups and small businesses looking to minimize initial production costs.

2. Cost-Effectiveness

While the initial setup cost for CNC machining may seem high, it proves economical in the long run. The accuracy and efficiency reduce material waste and minimize the need for rework, saving money over time.

3. Consistent Quality

CNC machining ensures consistent quality across all parts, even in high-volume production. This repeatability makes it the preferred method for industries where uniformity is non-negotiable.

Choosing the Right CNC Machining Service

When selecting a CNC machining provider, consider the following factors:

| Factor | Importance |

|---|---|

| Material Expertise | Ensure the provider works with the materials you require. |

| Lead Time | Look for services with fast turnaround times for your project needs. |

| Customization | Verify their ability to handle custom prototypes and designs. |

| Quality Assurance | Check for certifications and quality control measures. |

Conclusion:

CNC machining services offer unmatched precision, efficiency, and versatility, making them the go-to solution for creating custom and complex parts. Whether you need custom prototypes for a new product or high-volume production of precision components, custom CNC services ensure that your parts meet the highest standards of quality.By leveraging the benefits of CNC machining, businesses can achieve superior results while reducing costs and production time. Partnering with the right provider ensures that your project runs smoothly from start to finish, delivering parts that meet both functional and aesthetic requirements.Ready to take your manufacturing to the next level? Explore professional CNC machining services today and transform your designs into reality.