- Feb 10, 2025

Custom CNC machining is a pivotal technology that has revolutionized manufacturing processes across various industries. It allows businesses to create highly detailed and precise parts that are not only accurate but also cost-effective. Whether you’re in the aerospace, automotive, medical, or electronics sector, custom CNC machining provides unparalleled benefits for your manufacturing needs. This article will delve into how custom CNC machining works, its advantages, and why it's a game-changer for manufacturers.

What is Custom CNC Machining?

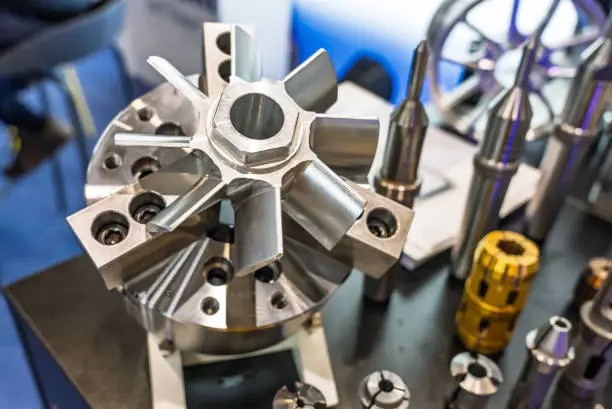

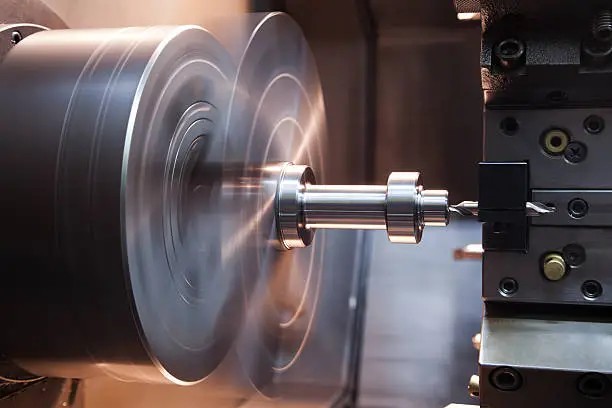

Custom CNC machining involves the use of computer-controlled machines to precisely shape and cut materials into specific parts based on a pre-programmed design. CNC, or Computer Numerical Control, allows for intricate and repeatable cuts, which makes it ideal for creating both prototypes and mass-produced components.

Unlike traditional machining methods, CNC machines follow digital instructions, ensuring consistent results with minimal human error. Custom CNC machining is used for a wide variety of materials, including metals, plastics, and composites, making it a versatile choice for businesses in need of highly customized parts.

The Key Advantages of Custom CNC Machining

Unmatched Precision and Accuracy

One of the biggest advantages of custom CNC machining is its ability to produce parts with extreme precision. With tolerances down to microns, CNC machining ensures that each component matches the design specifications to the smallest detail. This level of accuracy is critical for industries like aerospace and medical device manufacturing, where even the smallest discrepancy can lead to significant problems.Reduced Lead Times

Traditional machining processes can take weeks to set up, but CNC machines can be programmed and operational in a fraction of the time. This makes custom CNC machining an ideal choice for businesses that require quick turnaround times without compromising on quality. The automation of the process also reduces the time spent on manual labor, speeding up production cycles.Cost-Effective for Low and High-Volume Production

Although the initial setup cost for custom CNC machining can be higher than traditional methods, the long-term cost savings are significant. The ability to easily scale from small batches to large production runs without altering the setup is a key cost-saving feature. For prototype machining services, CNC machining is an excellent choice for creating low-volume, high-precision parts that are affordable and accurate.Complex Geometries and Designs

CNC machines can handle complex designs with ease, something that would be difficult or impossible with traditional machining methods. Custom CNC machining is ideal for manufacturing parts with intricate geometries, multi-axis cuts, and tight tolerances. Whether you need custom parts for prototypes or full production runs, CNC machines can meet your exact design specifications.Material Versatility

Another benefit of custom CNC machining is its ability to work with a wide range of materials. From metals like aluminum, steel, and titanium to plastics and composites, CNC machining allows manufacturers to produce parts using the materials that best suit their needs. This versatility makes it suitable for industries ranging from automotive to medical device manufacturing.Minimal Waste and Optimal Material Usage

Traditional machining methods often result in material waste, but custom CNC machining is highly efficient in material usage. The precision of the machine ensures that very little material is wasted, which helps reduce costs, especially when using expensive materials for prototypes or small production runs.

Why Choose CNC Machining for Prototype Manufacturing?

When it comes to prototype manufacturing companies, CNC machining is a top choice for producing accurate prototypes quickly and efficiently. Since prototypes often require multiple revisions and iterations, custom CNC machining can quickly adapt to changes in the design, enabling manufacturers to test and refine their products without significant delays.Additionally, the accuracy and precision of prototype machining services ensure that prototypes are functional and can undergo real-world testing before committing to full-scale production. This reduces the risk of costly mistakes and ensures that the final product will meet quality standards.

The Role of CNC Manufacturing Services in Mass Production

Once a prototype has been tested and refined, custom CNC machining can transition smoothly into mass production. CNC manufacturing services offer scalability, allowing businesses to produce both small batches and large quantities of high-precision components with minimal lead time. This scalability makes CNC machining an excellent option for businesses looking to scale their operations while maintaining consistent product quality.

Custom CNC machining has transformed the way manufacturers approach precision, efficiency, and cost-effectiveness. Whether you need highly detailed prototypes or mass-produced components, CNC machining provides the accuracy and flexibility necessary to meet your needs. By offering quick turnaround times, the ability to work with various materials, and the capability to produce complex designs, custom CNC machining is essential for businesses looking to stay ahead in today’s competitive market.