- Feb 19, 2025

Rapid prototype manufacturing has revolutionized the way products are developed and tested, offering faster turnaround times and cost-effective solutions. But how accurate is this process? For businesses and engineers, accuracy in prototyping is essential to ensure that the final product meets the required specifications.

Rapid prototype manufacturing involves creating physical models of a design quickly using advanced technologies like 3D rapid prototyping. This method offers exceptional accuracy, enabling businesses to develop prototypes that closely resemble the final product. The key advantage of rapid prototyping lies in its ability to translate digital designs into physical models with minimal variation.While traditional manufacturing methods often require lengthy processes and significant adjustments, rapid prototype manufacturing ensures that prototypes are produced with tight tolerances. Modern 3D printing and CNC machining techniques offer high precision, creating prototypes that closely match the specifications of the design. This accuracy is especially critical when designing functional parts or conducting stress tests.

The Role of 3D Rapid Prototyping

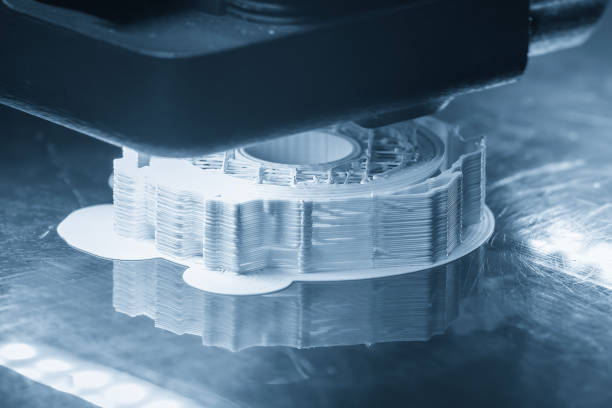

3D rapid prototyping has transformed the accuracy of prototype development. Using 3D printers, engineers can create prototypes layer by layer, ensuring a high degree of detail and precision. With the ability to print complex geometries and fine details, 3D rapid prototyping significantly enhances the accuracy of prototypes. The process allows for testing the physical form and fit of a product, providing insights into whether the design works as intended before proceeding to full-scale production.

The accuracy of 3D rapid prototyping can reach a tolerance of up to 0.1mm, depending on the printer and material used. This level of precision is ideal for testing prototypes in product design, as it helps uncover any potential issues that could affect the final product's functionality.

Prototype Development and Accuracy

In prototype development, the primary goal is to create a model that accurately represents the final product, not only in terms of aesthetics but also functionality. Rapid prototype manufacturing plays a crucial role in this by enabling developers to create high-accuracy prototypes that test the design’s real-world application.With rapid prototype manufacturing, designers can explore different materials, finishes, and features early in the design process. Whether you’re testing a consumer product or an industrial tool, having an accurate prototype ensures that design flaws are identified and fixed before mass production. This significantly reduces the risk of costly changes later in the process.

How Prototyping for Product Design Benefits from Accuracy

Accuracy in prototyping for product design is vital for several reasons. First, it allows designers to see how their ideas translate into physical forms, ensuring that proportions, fitting, and assembly methods are correct. Second, accurate prototypes help with the testing of functional features, such as how components will work together and whether they meet safety or performance standards.When a prototype is built with high accuracy through rapid prototype manufacturing, it becomes easier to evaluate the product’s usability and identify any design flaws. For example, if the prototype’s dimensions are slightly off, it could cause issues during assembly or functionality testing. Accurate prototypes eliminate these potential problems early in the design phase, ultimately leading to better end products.

How to Achieve High Accuracy in Rapid Prototyping

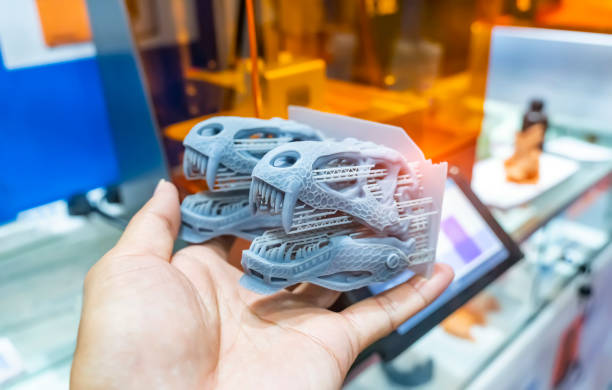

To achieve the highest level of accuracy in rapid prototype manufacturing, it is essential to select the right materials and technologies. For example, 3D rapid prototyping with SLA (Stereolithography) printers offers fine detail and smooth finishes, while FDM (Fused Deposition Modeling) offers reliable strength for functional testing. Choosing the correct material based on the application is also key to ensuring the prototype’s accuracy.Additionally, working with experienced prototype manufacturers can ensure the best results. Experts understand the nuances of different prototyping methods and can offer advice on which technique will deliver the most accurate results for your specific project.

Conclusion:

Rapid prototype manufacturing has proven to be an accurate and efficient method for creating product prototypes. With the help of 3D rapid prototyping and advanced technologies, prototype development has never been more precise. The accuracy of prototyping for product design plays a crucial role in ensuring that designs are tested and refined before full-scale production, leading to better end products and fewer costly mistakes. By embracing rapid prototype manufacturing, businesses can improve their product development cycles and bring innovations to market faster with greater confidence in the accuracy of their designs.