- Feb 26, 2025

For businesses working on complex designs, traditional prototyping methods may not always meet the demand. That's where CNC prototyping services come into play, offering an ideal solution for creating intricate, high-quality prototypes quickly and efficiently. Whether you're in the automotive, aerospace, or medical device sector, CNC machining provides a level of precision and flexibility that can turn even the most complicated concepts into reality. For companies like Oakon, specializing in CNC machining China, this technology is a game-changer in the prototyping process.

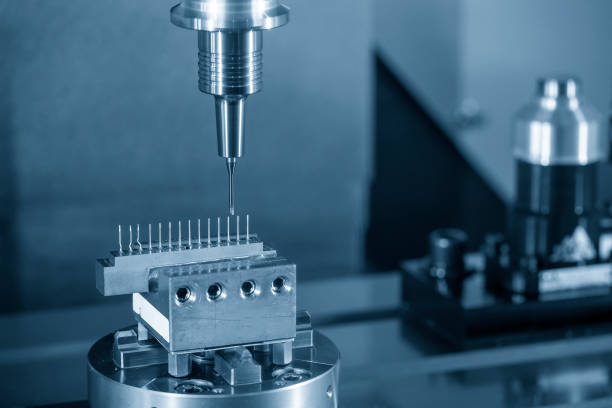

Precision and Accuracy in Complex Designs

One of the most significant advantages of CNC prototyping services is the unmatched precision it offers. CNC machining relies on computer-controlled machines to precisely cut, shape, and form materials based on a digital design. This technology ensures that every part of the prototype meets the exact specifications required, which is especially important for complex designs with tight tolerances.

Unlike manual methods, where human error can lead to slight deviations, CNC machining services ensure consistent results every time. The digital control of the machinery makes it easier to replicate intricate designs, which is why it's the preferred choice for producing prototypes that involve intricate geometries, sharp angles, or small features.

Speeding Up the Prototyping Process

In today's fast-paced market, time-to-market is critical. CNC prototyping services are incredibly efficient, allowing businesses to go from design to prototype in a fraction of the time compared to traditional methods. CNC machines can produce prototypes rapidly, cutting down the overall development timeline significantly. This is particularly valuable when refining complex designs or testing multiple iterations of a product before final production.

With CNC machining capabilities, even highly detailed and complicated designs can be manufactured quickly, giving companies a competitive edge in getting their products to market faster. This speed does not come at the cost of quality, as CNC machines can achieve high precision even with short turnaround times.

Flexibility to Work with Various Materials

CNC prototyping services are versatile, capable of working with a wide range of materials, from metals to plastics and composites. This is especially useful when dealing with complex designs that require specific material properties, such as strength, durability, or heat resistance. For instance, aerospace components often require materials like aluminum alloys, while medical device prototypes might need biocompatible plastics. CNC machining offers the flexibility to prototype in different materials based on the project requirements. Additionally, CNC machining China providers like Oakon have access to a vast array of high-quality materials and can source the best options for their clients. This flexibility allows businesses to test and refine their prototypes in the material that will eventually be used in the final product, ensuring that the design is feasible for mass production.

Cost-Effectiveness for Complex Designs

Another significant advantage of CNC prototyping services is their cost-effectiveness, especially when dealing with complex designs. Traditional prototyping methods like injection molding or casting can require expensive molds or tooling, which is not ideal when working with intricate or constantly changing designs. CNC prototyping eliminates the need for molds, reducing both the upfront cost and the risk of investing in an ineffective design.

In addition, CNC machining services offer scalability. Once the prototype is completed, the same machine and process can be used for small batch production runs, making it easy to transition from prototype to production without significant additional costs. This is particularly beneficial for businesses that need to iterate on complex designs before settling on a final version.

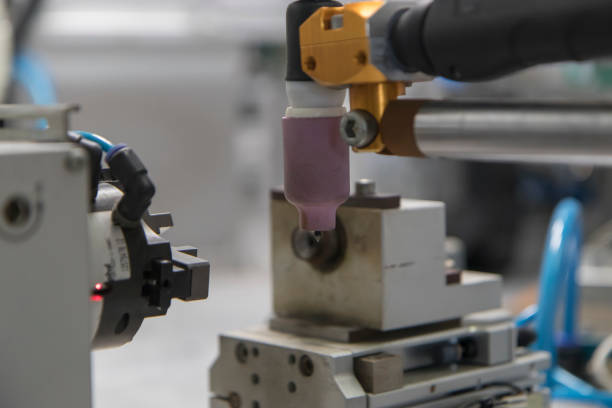

High-Quality Surface Finishes and Detail

For complex designs, surface finish quality is critical. In industries like automotive or consumer electronics, the visual and tactile quality of a prototype can make a huge difference in both function and market appeal. CNC prototyping services provide high-quality surface finishes, ensuring that every detail of a design is accurately represented. Advanced CNC machining techniques can produce smooth surfaces with minimal visible tool marks, which is essential for prototypes that need to look and feel like the final product. If the design calls for intricate detailing or delicate features, CNC machining ensures these elements are executed with precision, even if the design involves multiple layers, tight corners, or fine textures.

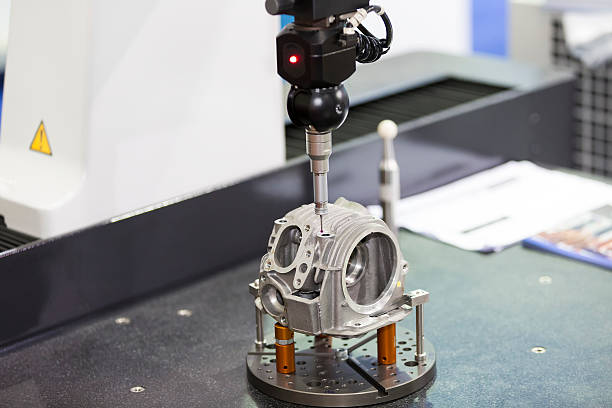

Proven Reliability for Complex Designs

As the demand for complex, high-performance designs increases across various industries, companies like Oakon, specializing in CNC machining China, have become leaders in the field. These manufacturers provide reliable and high-quality prototyping services that meet global standards. By leveraging advanced machinery and technology, they ensure that each project is completed with the highest levels of quality and precision.

Additionally, working with CNC machining service providers that have experience in complex designs can make a significant difference in the outcome. Experts can advise on the best machining methods and materials for specific design challenges, providing invaluable insight and ensuring the final prototype is both functional and manufacturable.

Conclusion:

For businesses in need of prototypes for complex designs, CNC prototyping services offer unparalleled advantages. From precision and speed to material flexibility and cost-effectiveness, CNC machining is the ideal solution for turning intricate ideas into reality. Companies like Oakon, specializing in CNC machining China, offer the expertise and technology to deliver high-quality prototypes, making it easier for businesses to refine designs, test functionality, and bring products to market faster. With CNC machining, complex designs are no longer a challenge—they are an opportunity for innovation and success.