- Feb 26, 2025

When it comes to creating prototypes, companies are increasingly turning to prototype machining services as a solution to streamline the process, save valuable time, and reduce costs. Whether you're designing a complex mechanical part or a new consumer product, prototype machining can significantly improve your development cycle. In this article, we’ll explore how prototype machining services can save both time and money for businesses, making it the ideal choice for many industries.

1. Faster Design Iterations

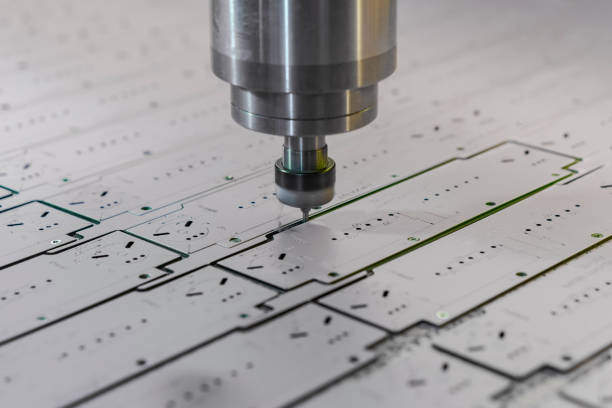

One of the biggest advantages of using prototype machining services is the speed at which prototypes can be produced. Traditional prototyping methods, such as molding or casting, can take a long time to set up and require expensive tools and molds. With CNC machining (a key component of prototype machining), companies can create parts quickly by directly machining them from a computer-aided design (CAD) model. This eliminates the need for time-consuming molds or manual labor and allows designers to iterate on their designs more rapidly. Faster iterations mean that companies can refine their products faster, cutting down the overall time spent in the development phase.

2. Reduced Need for Expensive Molds and Tools

Unlike other prototyping methods that require the creation of custom molds or tooling, prototype machining only requires the CAD model and the raw material. This reduces the upfront costs associated with developing prototypes. Traditional methods often involve significant expenses for creating molds and tooling, and if the design changes, the company may need to make new molds, which adds to the cost and delays the project. With CNC machining, companies can quickly modify the design and produce new prototypes without additional costs for molds. This flexibility helps businesses stay within budget and avoid unforeseen expenses.

3. Lower Production Costs for Small Batches

Another key benefit of prototype machining services is the cost-effectiveness for small batch production. Unlike injection molding or die casting, which require large minimum order quantities to be cost-effective, CNC machining allows for the production of small quantities without a significant increase in per-unit cost. Whether you're testing a handful of prototypes or small batches for market testing, CNC machining provides a cost-effective way to produce parts in limited quantities without the usual setup costs that come with mass production methods. This flexibility is ideal for businesses looking to test prototypes without committing to large-scale production runs.

4. Improved Accuracy and Quality

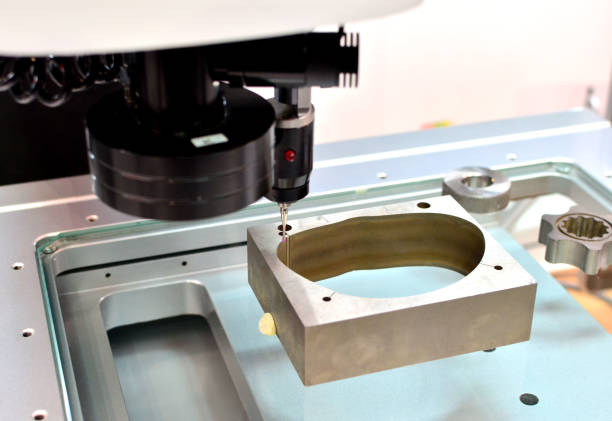

Prototype machining services provide high precision and tight tolerances, ensuring that the prototypes are as close to the final product as possible. This eliminates the need for costly rework or adjustments later in the process. With traditional methods, variations in prototypes may require further adjustments during testing, resulting in wasted time and additional expenses. On the other hand, CNC machining allows for consistency and accuracy, helping companies avoid the costs associated with prototype flaws. The high-quality finish and accurate dimensions also mean that prototypes can be tested more effectively in real-world applications, helping to reduce the number of design changes required later.

5. Reduced Risk of Design Flaws

By using prototype machining services, companies can test their designs earlier in the development process and catch design flaws before they become costly issues. Early-stage testing allows businesses to identify and correct any problems with the design, material selection, or functionality before moving to mass production. Fixing issues in the prototype stage is far less expensive than addressing problems in production. Moreover, CNC machining allows for a more thorough testing process because prototypes produced using this method are highly accurate. By catching issues early, businesses can prevent costly mistakes that might arise from design flaws that weren’t detected in the prototype phase.

6. Access to a Range of Materials

Prototype machining services allow businesses to choose from a wide range of materials, including metals, plastics, and composites, which gives them the flexibility to test different options before committing to a material for full-scale production. This access to diverse material options allows companies to optimize their prototypes for cost, durability, and functionality. Testing prototypes in different materials can also help determine the most cost-effective option for final production, reducing the risk of selecting an unsuitable material that could drive up costs later.

7. Faster Time-to-Market

Ultimately, prototype machining services allow businesses to reduce their time-to-market. By speeding up the prototyping phase, companies can move more quickly to production. The faster development cycle also enables businesses to respond to market trends or customer demands more effectively. In competitive industries, being first to market can provide a significant advantage, and prototype machining allows businesses to accelerate the product development process without sacrificing quality.

Once a prototype is finalized using prototype machining services, the same machines and techniques can be used for low-volume production. This scalability reduces the risk of having to retool or invest in new equipment when transitioning from prototyping to production. With CNC machining, businesses can continue producing small quantities or scale up their production gradually without significant additional costs. This helps companies manage their resources efficiently and avoid unnecessary expenditures.

In today’s competitive market, businesses must focus on speed and cost-efficiency to stay ahead. Prototype machining services offer significant advantages in both time and cost savings by reducing the need for expensive molds, providing faster design iterations, and improving the accuracy and quality of prototypes. With CNC machining, companies can streamline their prototyping process, reduce the risks associated with design flaws, and ultimately bring their products to market more quickly. Whether you’re in the early stages of product development or looking to refine an existing design, prototype machining is an essential tool that can help save both time and money.