- Dec 23, 2023

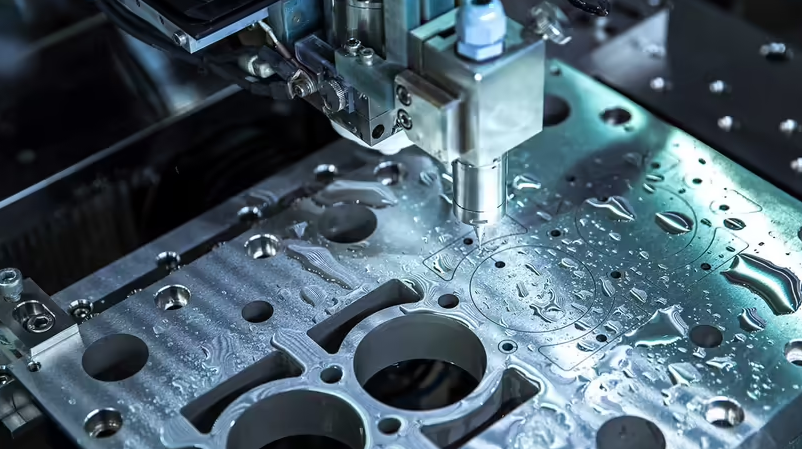

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that utilizes computerized systems to control machine tools. It is a versatile and highly efficient method widely used in various industries to produce complex and precise parts.

What is CNC Machining?

CNC machining involves the use of computer-controlled machines to remove material from a workpiece to shape and create the desired product. The machines follow a set of programmed instructions, which dictate the specific movements and actions needed to produce the final part.

The CNC Machine Setup Process

The CNC machine setup process involves several key steps:

- Design and Programming: The first step is to create a digital design of the part using Computer-Aided Design (CAD) software. Based on the design, a program is generated using Computer-Aided Manufacturing (CAM) software that contains instructions for the CNC machine.

- Machine Setup: Once the program is ready, the workpiece is secured on the CNC machine's bed or table. The appropriate cutting tools are selected and installed in the machine.

- Tool Path Generation: The program instructs the machine on the specific tool paths to follow for machining the part. This includes the cutting depths, speeds, and directions.

- Execution: With everything in place, the CNC machine executes the program and begins the machining process. The machine precisely moves the cutting tools across the workpiece to remove material and create the desired shape.

Advantages of CNC Machining

CNC machining offers several advantages over conventional machining methods:

- Precision: CNC machines provide exceptional precision, allowing for the production of complex and accurate parts.

- Efficiency: The automated nature of CNC machines significantly reduces human error and increases production efficiency.

- Repeatability: CNC machines can repeatedly produce the same part with high accuracy, making them suitable for mass production.

- Versatility: CNC machines can work with various materials, including metals, plastics, and wood.

Applications of CNC Machining

CNC machining finds applications in several industries, including:

- Automotive: CNC machining is used to create engine components, transmission parts, and custom automotive parts.

- Aerospace: Precision is crucial in aerospace, and CNC machining is used to create complex parts for aircraft and spacecraft.

- Medical: CNC machining produces intricate surgical tools, implants, and prosthetics.

- Electronics: CNC machining is utilized to create custom electronic components with high precision.

Conclusion

CNC machining is a sophisticated manufacturing process that offers precision, efficiency, and versatility. Its wide range of applications and ability to produce intricate parts make it an indispensable technology in modern industries. With continuous advancements and improvements, CNC machining continues to play a vital role in shaping the future of manufacturing.