- Jan 08, 2024

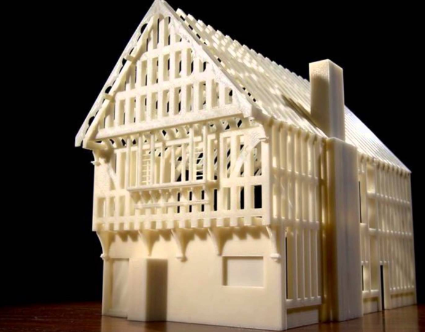

The realm of 3D printing has revolutionized the way we approach manufacturing and prototyping, offering unparalleled flexibility and customization. To ensure the creation of perfect 3D printed parts, one must navigate various considerations ranging from design and material selection to printer settings and post-processing techniques. This comprehensive guide explores the key steps and best practices for achieving flawless 3D printed components.

1. Begin with a Robust Design: The Foundation of Perfection

The journey towards perfect 3D printed parts commences with a robust and well-thought-out design. Utilize professional 3D modeling software, ensuring that your design accounts for structural integrity, support structures, and printability. Pay careful attention to details such as overhangs, bridges, and intricate features to optimize the printability of your model.

2. Material Selection: Choosing the Right Substance for the Job

Selecting the appropriate printing material is pivotal in achieving perfect 3D printed parts. Various materials, including PLA, ABS, PETG, and specialty filaments, offer unique properties suitable for different applications. Consider factors such as strength, flexibility, heat resistance, and post-processing requirements when choosing the material for your specific project.

3. Calibration Matters: Fine-Tuning Your 3D Printer

Calibrating your 3D printer is a crucial step in achieving precision. Ensure that your printer's bed is level, the extruder is properly calibrated, and the temperature settings align with the chosen filament. Regular calibration checks prevent issues like layer shifting, poor adhesion, and inaccuracies in dimensions, all of which can impact the quality of the final print.

4. Temperature Control: Striking the Right Balance

Maintaining optimal temperature conditions during the printing process is essential for obtaining perfect 3D printed parts. Fine-tune nozzle and bed temperatures to match the material specifications. Consistent temperature control helps prevent issues like warping, stringing, and layer adhesion problems, ensuring a smooth and flawless print.

5. Support Structures: Providing Stability for Complex Designs

Incorporate support structures intelligently into your design to provide stability for overhangs and complex geometries. Experiment with different support settings in your slicing software to strike a balance between providing adequate support and ensuring ease of removal during post-processing.

6. Layer Height and Resolution: Balancing Precision and Print Time

Adjusting layer height and print resolution is a delicate balancing act. While lower layer heights offer increased precision, they also result in longer print times. Find the optimal compromise for your project, considering the desired level of detail and the practical constraints of time and resources.

7. Post-Processing Techniques: Refining the Final Product

Perfecting 3D printed parts often involves post-processing to refine the surface finish and address imperfections. Techniques such as sanding, polishing, and applying surface coatings can enhance the aesthetics of the printed component. Additionally, consider utilizing support material removal methods for intricate designs.

8. Quality Check: Vigilance for Consistent Excellence

Conduct a thorough quality check upon completing the print. Inspect for layer consistency, dimensional accuracy, and any visible defects. Implementing a meticulous quality control process ensures that each 3D printed part meets the desired specifications and performance standards.

Conclusion: Crafting Excellence in Every Layer

In the pursuit of perfect 3D printed parts, the synergy of design, material selection, calibration, and post-processing techniques is paramount. By paying meticulous attention to each step of the process and embracing a mindset of continuous improvement, one can unlock the full potential of 3D printing technology to produce flawless and functional components. Whether for prototyping, manufacturing, or creative endeavors, the journey towards perfection in 3D printing is an ongoing exploration of innovation and precision.