- Dec 23, 2023

Silicone replica mold, also known as vacuum replica mold, refers to using the original template to make a silicone mold in a vacuum state, and casting it using PU, silicone, nylon, ABS and other materials in a vacuum state, thereby cloning the original mold. For copies of the same model, the restoration rate reaches 99.8%.

Silicone replica mold process

Silicone molding materials include: ABS, PC, PP, PMMA, PVC, rubber, high temperature resistant materials and other materials.

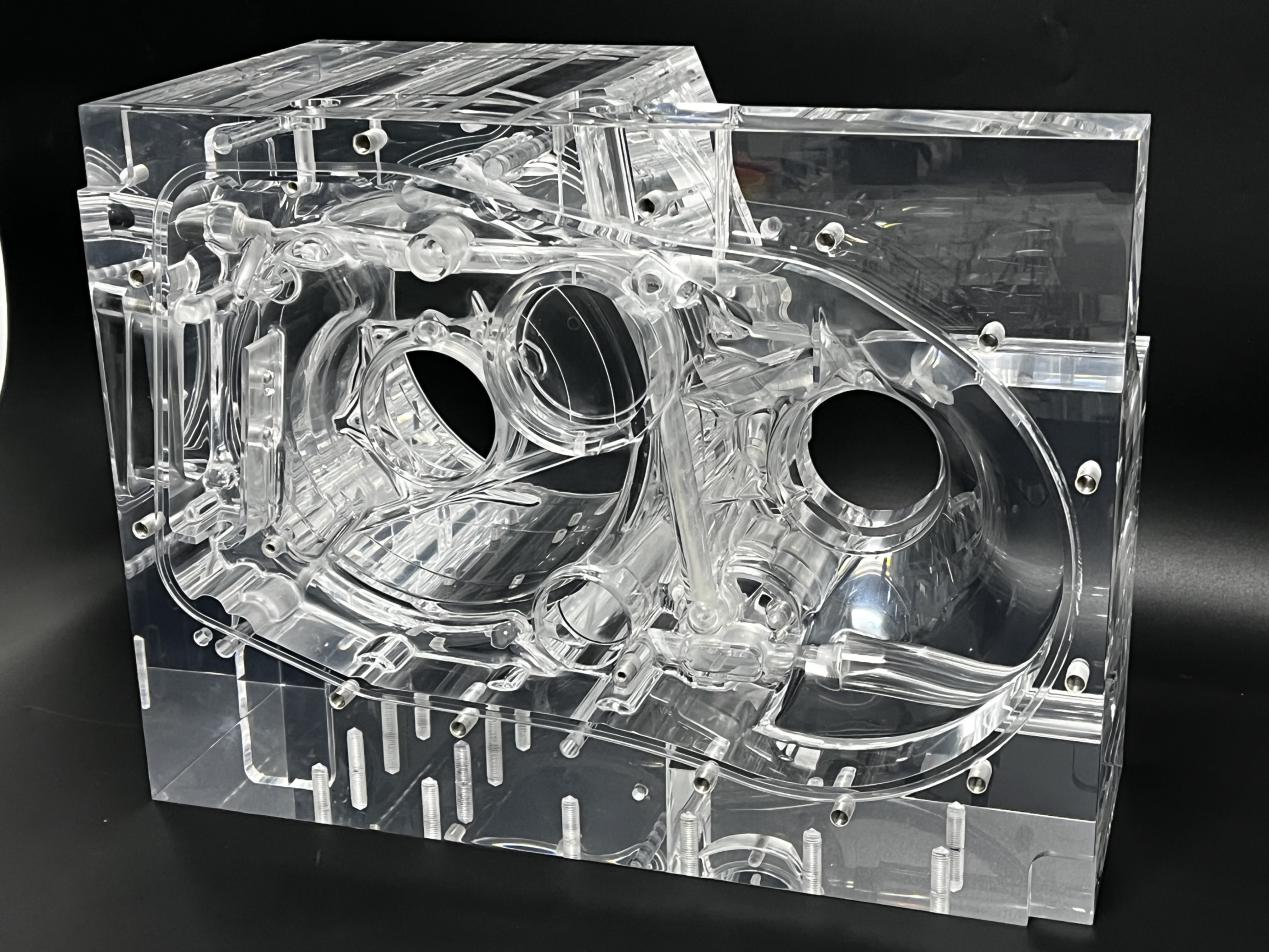

1. Prototype manufacturing: According to the 3D drawings provided by the customer, the prototype is manufactured through CNC processing, SLA laser rapid prototyping or 3D printing.

2. Pour the silicone mold: After making the prototype, make the mold base, fix the prototype, pour the silicone, and after drying for 8 hours, open the mold and take out the prototype, and the silicone mold is completed.

3. Injection molding: Inject the liquid plastic material into the silicone mold, and then cure it in a constant temperature oven at 60°-70° for 30-60 minutes before demoulding. If necessary, in a constant temperature oven at 70°-80° Allow 2-3 hours for secondary curing. Under normal circumstances, the service life of silicone molds is 15-20 times.

What are the applications of silicone replica molds?

1. Plastic prototypes: The raw materials are plastics, mainly prototypes of some plastic products, such as TVs, monitors, telephones, etc. The most common photosensitive resin used in 3D prototyping is plastic prototypes.

2. Silicone laminated prototypes: The raw material is silica gel. They are mainly prototypes that display the design appearance of products, such as cars, mobile phones, toys, handicrafts, daily necessities, etc.