- Feb 24, 2024

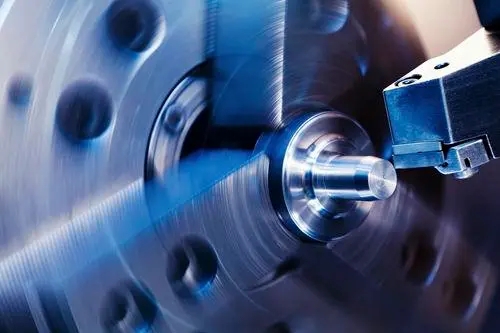

In today's fast-paced manufacturing industry, companies are constantly seeking innovative solutions to bring their ideas to life quickly and efficiently. One such solution that has gained significant popularity is rapid CNC prototyping. Combining the precision of CNC machining with the speed of rapid prototyping, this advanced manufacturing process offers numerous advantages for businesses looking to streamline their production processes.

Rapid CNC prototyping, also known as prototype machining or rapid CNC machining, utilizes computer numerical control (CNC) technology to create highly accurate prototypes and functional parts from a variety of materials. By integrating rapid prototyping techniques with CNC machining capabilities, manufacturers can produce prototypes and low-volume production parts with unmatched speed and precision.

One of the primary reasons to choose rapid CNC prototyping for your manufacturing needs is its unparalleled speed and efficiency. Traditional prototyping methods can be time-consuming and labor-intensive, requiring extensive manual labor and multiple iterations to achieve the desired results. In contrast, rapid CNC prototyping allows for rapid iteration and quick turnaround times, enabling businesses to accelerate their product development cycles and bring new products to market faster than ever before.

Moreover, rapid CNC prototyping offers superior precision and accuracy, ensuring that prototypes and production parts meet the exact specifications and tolerances required for their intended applications. With advanced CNC machining capabilities, manufacturers can achieve tight tolerances, complex geometries, and intricate designs with ease, resulting in high-quality parts that perform reliably in real-world environments.

Another compelling reason to choose rapid CNC prototyping is its versatility and flexibility. Unlike traditional manufacturing methods that may be limited by tooling constraints or material availability, rapid CNC prototyping can accommodate a wide range of materials, including metals, plastics, composites, and more. This versatility allows manufacturers to explore different materials and design concepts during the prototyping phase, helping to identify the most cost-effective and efficient solutions for their production needs.

Furthermore, rapid CNC prototyping offers cost-effective solutions for both prototype development and low-volume production runs. By minimizing material waste and reducing setup times, CNC machining quote estimates are typically lower compared to traditional machining methods, making rapid CNC prototyping a cost-effective option for businesses of all sizes.

In conclusion, rapid CNC prototyping is a highly efficient and versatile manufacturing solution that offers numerous advantages for businesses looking to accelerate their product development cycles and bring new products to market quickly and cost-effectively. With its unmatched speed, precision, and flexibility, rapid CNC prototyping has become the go-to choice for companies seeking to stay ahead of the competition in today's fast-paced manufacturing landscape. Whether you're prototyping a new product or producing low-volume production parts, rapid CNC prototyping is the ideal solution for your manufacturing needs.