- May 21, 2024

Sheet metal working is a highly versatile and widely used set of techniques that involve manipulating thin sheets of metal to create various products. There are four primary types of sheet metal working, each with its unique processes and applications. In this article, we will explore these four types in detail and understand their significance in the field of metal fabrication.

1. Cutting

Cutting is the first and most fundamental step in sheet metal working. It involves separating a piece of metal into the desired shape by removing excess material. There are several methods of cutting, including manual cutting, shearing, and laser cutting. Manual cutting relies on hand tools such as tin snips or power tools like plasma cutters to achieve precise cuts. Shearing applies a strong force to cut through the metal while laser cutting employs high-intensity laser beams to vaporize the material along the intended path. These cutting techniques are crucial for creating the initial shape of the metal sheet.

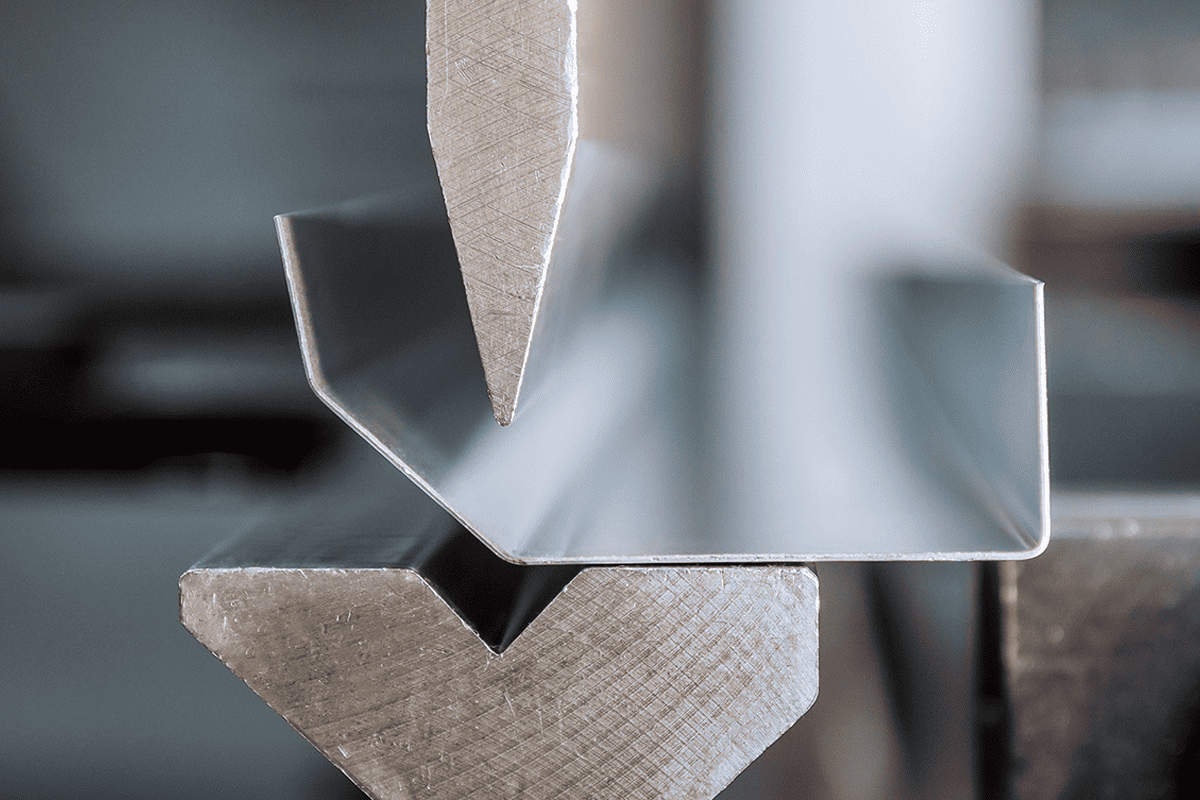

2. Bending

Bending is a technique used to reshape the metal sheet by applying force along a straight axis. This process allows the creation of angles, curves, and various other geometric shapes. The most common method of bending is the use of press brakes, which utilize a punch and die set to deform the metal sheet according to a specific design. Bending has wide applications in industries such as automotive, aerospace, and construction, where complex shapes and structures are often required.

3. Forming

Forming involves changing the shape of the metal sheet without cutting or bending it. This technique relies on external forces to deform the material, resulting in a desired shape. Examples of forming include deep drawing, where a sheet metal blank is transformed into a hollow shape using a punch and die, and roll forming, which involves passing the metal sheet through a series of rollers to achieve a desired profile. Forming is frequently used in the production of utensils, HVAC systems, and automotive components.

4. Joining

Joining is the process of connecting multiple metal sheets together to create a more complex structure. It is often crucial in manufacturing large-scale products or assembling various components to form a coherent whole. There are several methods of joining, including welding, riveting, and adhesive bonding. Welding involves melting the metal sheets and fusing them together using heat and pressure. Riveting uses mechanical fasteners called rivets to hold the sheets together, while adhesive bonding relies on strong adhesives to create a bond. Joining is common in industries such as shipbuilding, construction, and automotive manufacturing.

Conclusion

Sheet metal working encompasses a wide range of techniques, each serving its specific purpose in the fabrication process. Cutting, bending, forming, and joining are the four main types that form the foundation of sheet metal working. By understanding and utilizing these techniques effectively, manufacturers can create intricate designs, efficient structures, and functional products across numerous industries.