- Apr 11, 2024

Plastic injection molding is a widely used manufacturing process for producing plastic parts in large volumes with high precision and efficiency. One of the critical factors influencing the success of injection molding is the selection of the appropriate type of plastic material. In this article, we will delve into the various types of plastic used in injection molding, their properties, applications, and considerations for choosing the right material.

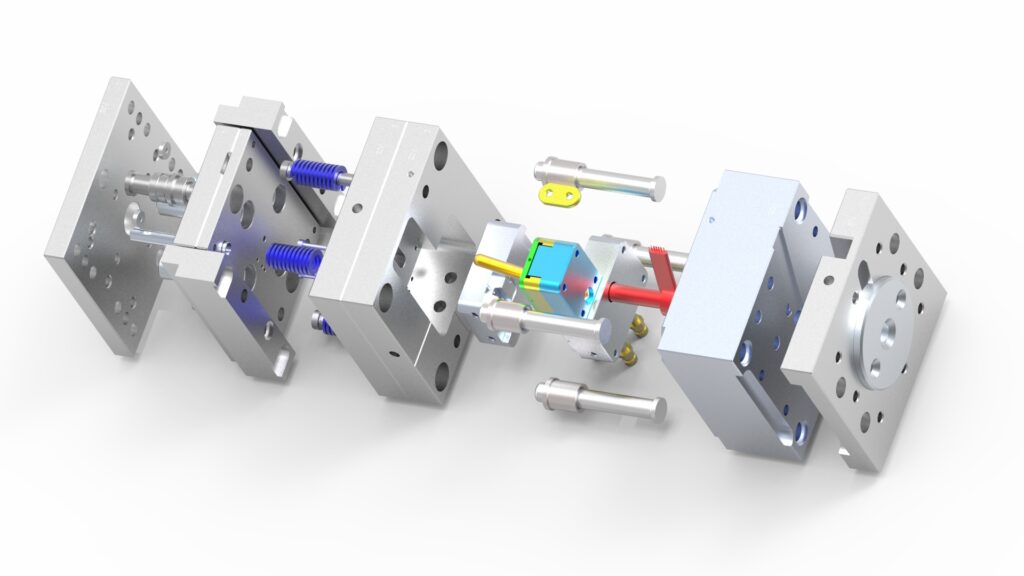

Before delving into the types of plastic materials, let's briefly review the plastic injection molding process. Plastic injection molding involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape of the final product. This process is highly versatile and is used to manufacture a wide range of products across industries, including automotive, aerospace, medical, consumer goods, and electronics.

Types of Plastic Materials for Injection Molding

1. Polyethylene (PE): Polyethylene is one of the most commonly used plastics in injection molding due to its versatility, durability, and low cost. It comes in various forms, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), each with its unique properties. PE is used in a wide range of applications, including packaging, containers, pipes, and toys.

2. Polypropylene (PP): Polypropylene is another popular choice for injection molding due to its excellent chemical resistance, stiffness, and heat resistance. It is commonly used in automotive parts, appliances, packaging, and medical devices.

3. Polystyrene (PS): Polystyrene is known for its clarity, rigidity, and ease of processing, making it suitable for a variety of injection molding applications. It is commonly used in packaging, disposable cutlery, CD cases, and consumer electronics.

4. Acrylonitrile Butadiene Styrene (ABS): ABS is a versatile thermoplastic known for its excellent impact resistance, toughness, and dimensional stability. It is commonly used in automotive parts, electronic housings, toys, and consumer goods.

5. Polyvinyl Chloride (PVC): PVC is a widely used thermoplastic known for its durability, chemical resistance, and flame retardancy. It is commonly used in construction materials, pipes, fittings, and medical devices.

6. Polyethylene Terephthalate (PET): PET is a transparent, lightweight plastic known for its excellent barrier properties and recyclability. It is commonly used in packaging, beverage bottles, and textile fibers.

7. Polycarbonate (PC): Polycarbonate is a transparent thermoplastic known for its high impact resistance, optical clarity, and heat resistance. It is commonly used in automotive components, electronic housings, and medical devices.

8. Nylon (PA): Nylon is a versatile engineering thermoplastic known for its high strength, toughness, and abrasion resistance. It is commonly used in automotive parts, gears, bearings, and electrical connectors.

Considerations for Material Selection

When selecting a plastic material for injection molding, several factors should be considered:

Mechanical Properties: Consider the desired mechanical properties of the final product, such as strength, stiffness, impact resistance, and flexibility.

Chemical Resistance: Evaluate the material's resistance to chemicals, solvents, and environmental factors to ensure compatibility with the intended application.

Temperature Resistance: Consider the operating temperature range of the product and select a material with appropriate heat resistance properties.

Appearance and Surface Finish: Choose a material that meets aesthetic requirements and can achieve the desired surface finish, texture, and color.

Cost: Consider the cost of the material, including raw material cost, processing cost, and any additional finishing or post-processing requirements.

The selection of the appropriate plastic material is crucial for the success of injection molding plastic. With a wide range of plastics available, each with its unique properties and applications, careful consideration should be given to factors such as mechanical properties, chemical resistance, temperature resistance, appearance, and cost. By choosing the right material for the job, manufacturers can ensure the production of high-quality plastic parts that meet the requirements of their intended application.