- Apr 15, 2024

In the realm of manufacturing, precision and accuracy are paramount, dictating the success and reliability of end products. CNC (Computer Numerical Control) machining has emerged as a cornerstone technology, revolutionizing the production landscape with its ability to deliver exceptional quality and precision. In this article, we delve into the profound impact of CNC machining on product quality and accuracy, shedding light on its benefits and transformative capabilities.

Understanding CNC Machining

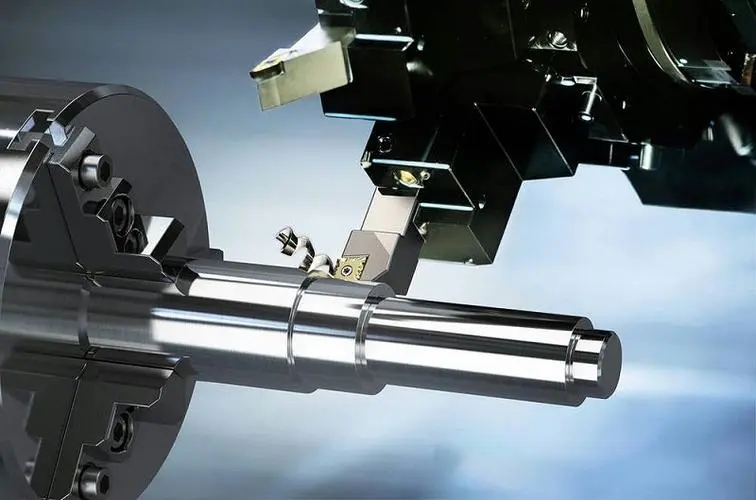

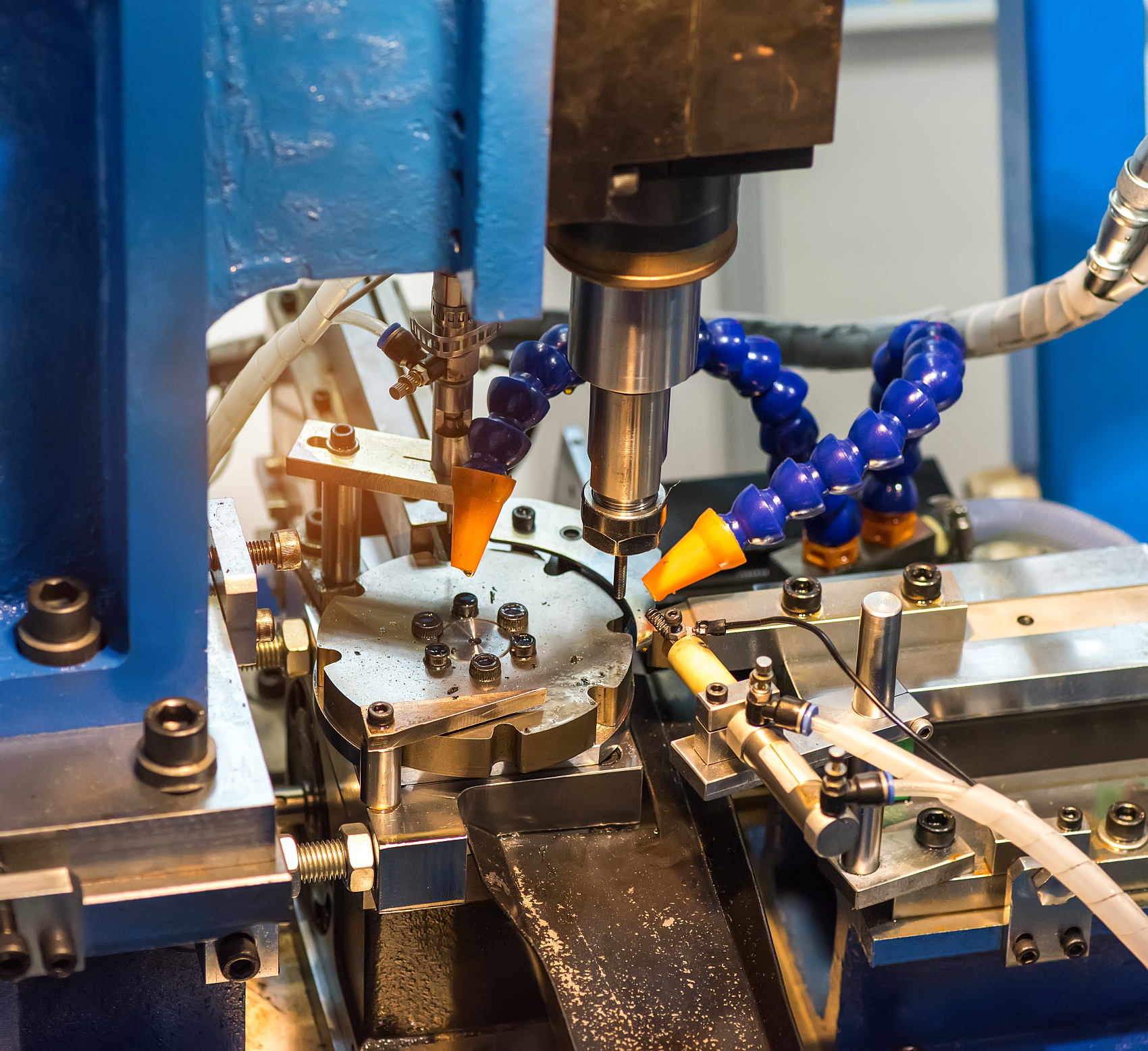

CNC machining involves the use of computer-controlled machines to fabricate complex components with unparalleled precision and accuracy. Through precise instructions programmed into the CNC system, raw materials are meticulously carved and shaped into intricate designs, ensuring consistency and repeatability in every iteration.CNC machining services offered by manufacturers play a pivotal role in streamlining the production process and elevating product quality. By harnessing advanced machinery and expertise, CNC machining manufacturers can cater to diverse industry needs while adhering to stringent quality standards.

Impact on Product Quality

1. Enhanced Precision

CNC machining excels in achieving intricate designs and tight tolerances, resulting in components that meet precise specifications with minimal deviation. This level of precision ensures uniformity and consistency across production batches, bolstering overall product quality.

2. Superior Surface Finish

The precision of CNC machining translates into superior surface finishes, minimizing roughness and imperfections. Smooth surfaces not only enhance aesthetics but also optimize functionality, particularly in applications where friction and wear resistance are critical.

3. Reduced Error Margin

Automation inherent in CNC machining minimizes the risk of human error, eliminating variability introduced by manual intervention. This reduction in error margin enhances product reliability and minimizes the likelihood of defects, ensuring customer satisfaction and loyalty.

Impact on Accuracy

1. Consistent Performance

CNC machining's ability to execute programmed instructions with unparalleled accuracy ensures consistent performance across all manufactured components. Whether producing intricate prototypes or mass-producing parts, CNC machines deliver reliability and accuracy without compromise.

2. Tight Tolerance Control

The precise control afforded by CNC machining enables manufacturers to maintain tight tolerances, meeting exacting requirements dictated by design specifications. This level of accuracy is indispensable in industries where even slight deviations can compromise product functionality and performance.

3. Flexibility and Adaptability

CNC machining's versatility allows for rapid prototyping and iterative design processes, facilitating quick adjustments and modifications without sacrificing accuracy. This adaptability ensures that products evolve seamlessly to meet evolving market demands and customer preferences.

The Future of CNC Machining

As technology continues to advance, the impact of CNC machining on product quality and accuracy will only intensify. Manufacturers leveraging CNC machining online platforms will unlock new possibilities in customization, efficiency, and innovation, driving the evolution of manufacturing landscapes worldwide.

CNC machining stands as a cornerstone technology in modern manufacturing, redefining standards of product quality and accuracy. Through its precision, consistency, and adaptability, CNC machining services offered by manufacturers online pave the way for unparalleled excellence in every component produced. As industries embrace the transformative potential of CNC machining, the future holds promise for innovation, efficiency, and limitless possibilities.