- Apr 24, 2024

In the fast-paced world of manufacturing, efficiency is paramount. Companies constantly seek ways to streamline processes, reduce costs, and bring products to market quicker than ever before. One crucial aspect of this journey is the prototyping process, where ideas are transformed into tangible products ready for mass production. Oakon, a prominent player in the prototyping services industry in China, stands out for its commitment to efficiency. Let's delve into how Oakon achieves this, focusing on its expertise in plastic injection molding and machining manufacturing.Prototyping services encompass a range of techniques used to create preliminary versions of products. These prototypes serve multiple purposes: they help validate designs, identify potential issues early in the development cycle, and allow for testing and refinement before full-scale production begins.

Oakon's Approach to Efficiency

Advanced Technology Integration

Oftentimes, the efficiency of a prototyping process is directly tied to the technology employed. Oakon understands this well and invests in cutting-edge equipment and software to optimize its operations. From state-of-the-art 3D printers for rapid prototyping to advanced CNC machines for precise machining, Oakon leverages technology to accelerate the prototyping timeline without compromising on quality.

Seamless Workflow Integration

Efficiency is not just about individual machines or processes; it's about how these elements come together seamlessly. Oakon's prototyping process is characterized by a well-defined workflow, where each step flows seamlessly into the next. From initial design consultation to final product delivery, every stage is meticulously planned and executed, minimizing delays and maximizing throughput.

Agile Project Management

Flexibility is key in the world of prototyping, where changes and iterations are commonplace. Oakon adopts an agile approach to project management, allowing for quick adjustments in response to evolving requirements. Whether it's modifying design specifications or adjusting production schedules, Oakon's team remains nimble, ensuring that projects stay on track without sacrificing efficiency.

Plastic Injection Molding: A Cornerstone of Oakon's Expertise

Plastic injection molding is a cornerstone of modern manufacturing, offering unparalleled versatility and cost-effectiveness. Oakon specializes in this technique, utilizing advanced machinery and proprietary processes to deliver high-quality plastic parts with exceptional efficiency.

Precision Tooling

Central to the success of any injection molding project is the quality of the molds. Oakon boasts in-house tooling capabilities, allowing for the rapid design and fabrication of precision molds tailored to each client's specifications. By controlling the entire tooling process, Oakon ensures tight tolerances, minimal lead times, and cost-effective solutions for its customers.

Streamlined Production

Efficiency in injection molding extends beyond tooling to the production floor. Oakon's manufacturing facilities are optimized for maximum throughput, with automated processes and lean manufacturing principles driving productivity. By minimizing setup times, reducing material waste, and optimizing cycle times, Oakon delivers plastic injection molded parts quickly and cost-effectively, meeting even the most demanding project deadlines.

Machining Manufacturing: Precision Redefined

In addition to plastic injection molding, Oakon offers comprehensive machining manufacturing services, catering to clients with exacting requirements for precision components.

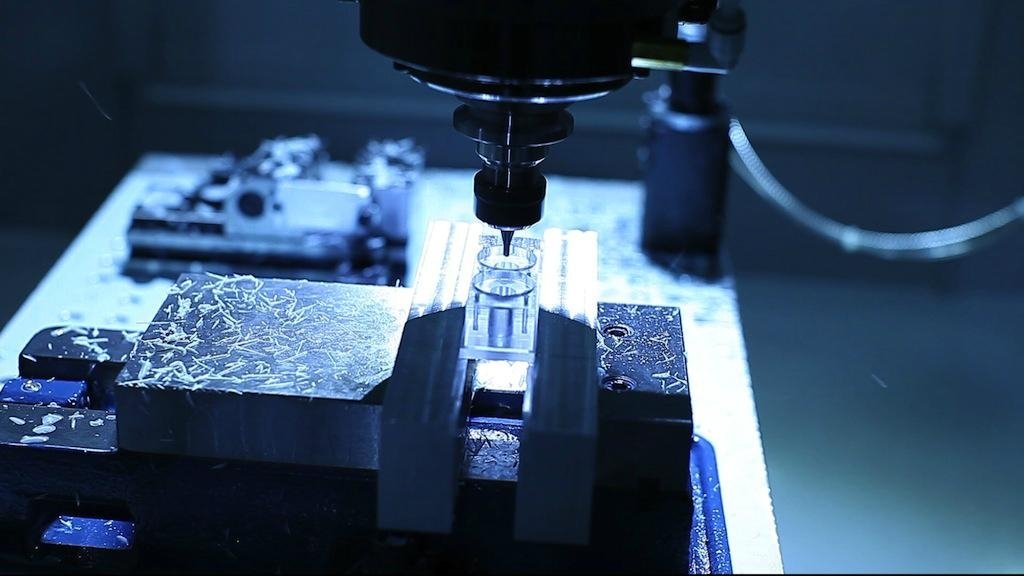

State-of-the-Art CNC Machining

At the heart of Oakon's machining capabilities are its advanced CNC machines. These computer-controlled marvels enable the precise fabrication of complex parts with tight tolerances and repeatability. Whether it's milling, turning, or grinding, Oakon's CNC machining centers deliver unparalleled accuracy and efficiency, ensuring that every component meets the highest quality standards.

Rapid Prototyping with CNC Machining

One of the key advantages of CNC machining is its suitability for rapid prototyping. Unlike traditional tooling methods, which may require weeks or even months to produce molds or dies, CNC machining allows for the rapid fabrication of prototype parts directly from digital designs. This accelerated turnaround time enables Oakon's clients to iterate quickly, testing and refining their designs without the prolonged delays associated with conventional prototyping methods.

Efficiency is the lifeblood of modern manufacturing, and Oakon exemplifies this ethos in its prototyping process. Through advanced technology integration, seamless workflow integration, and agile project management, Oakon delivers rapid, cost-effective prototyping solutions to its clients. Whether leveraging the versatility of plastic injection molding or the precision of CNC machining, Oakon remains at the forefront of innovation, driving the industry forward with its unwavering commitment to efficiency.