- Apr 30, 2024

CNC machining has revolutionized the automotive industry, offering unparalleled precision, efficiency, and versatility in the design and production of automotive components. From prototyping to custom manufacturing, CNC machining plays a crucial role in shaping the future of automotive design. In this article, we explore the impact of CNC machining on automotive design processes, highlighting its role in prototyping, custom manufacturing, and cost-effectiveness.

1.Prototyping with CNC Machining:

One of the key advantages of CNC machining in automotive design is its ability to facilitate rapid prototyping. CNC machining allows designers and engineers to quickly and accurately create prototypes of automotive components, enabling them to test and refine designs before moving into full-scale production. By leveraging CNC machining prototyping capabilities, automotive manufacturers can accelerate the product development cycle, reduce time-to-market, and minimize costly errors.

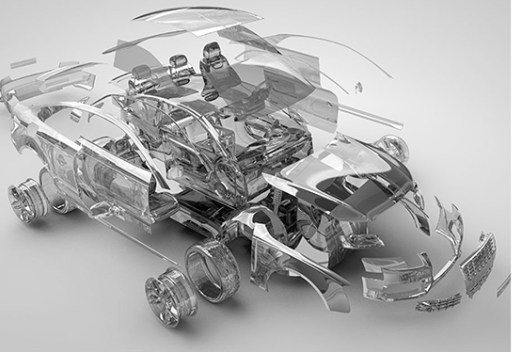

2.Custom CNC Machining for Automotive Components:

In addition to prototyping, custom CNC machining plays a vital role in the production of custom automotive components. From engine parts to interior trim, CNC machining enables manufacturers to create complex, precision-engineered components tailored to specific vehicle models and performance requirements. With advanced CAD/CAM software and CNC machine tools, automotive designers can bring their vision to life with unparalleled accuracy and consistency.

3.Cost-Effectiveness of CNC Machining:

While CNC machining offers superior precision and customization capabilities, it also delivers cost-effective solutions for automotive design and production. Despite the initial investment in CNC machine tools and equipment, the long-term benefits of CNC machining far outweigh the costs. By optimizing production processes, reducing material waste, and streamlining workflows, CNC machining helps automotive manufacturers improve efficiency and profitability. Moreover, advancements in CNC technology have led to more affordable CNC machine prices, making it accessible to a wider range of automotive businesses.

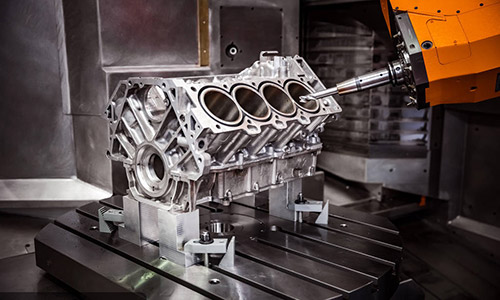

4.Precision Engineering in Automotive Design:

At the heart of CNC machining's impact on automotive design is its unparalleled precision engineering capabilities. CNC machining enables designers to achieve tight tolerances and intricate geometries that are essential for optimal performance and functionality in automotive components. Whether it's machining engine blocks, transmission parts, or suspension components, CNC machining delivers precise results that meet the rigorous standards of the automotive industry.

CNC machining plays a transformative role in shaping automotive design processes. From rapid prototyping to custom manufacturing, CNC machining offers unparalleled precision, efficiency, and cost-effectiveness for automotive manufacturers. By leveraging CNC machining prototyping capabilities, custom CNC machining services, and affordable CNC machine prices, automotive designers and engineers can innovate with confidence, bringing cutting-edge designs to life with precision and accuracy. As the automotive industry continues to evolve, CNC machining will remain at the forefront of innovation, driving advancements in design, performance, and efficiency.