- Jun 13, 2024

The competitiveness of CNC factory in the future will hinge on several key factors. As technology and industry demands evolve, CNC workshops will need to adapt and innovate to maintain their edge. Here are some critical areas that will shape their future competitiveness:

1. Multi-tasking Lathes and Five-axis Machining Centers

Five-axis machining centers have become the standard configuration when purchasing new machining centers. Some companies are intimidated by these machines, but they are easier to set up than horizontal machining centers. Most cnc companies find them more difficult to program. If you are doing full five-axis programming, most companies use them for five-axis positioning, which is much easier. Multi-tasking lathes are also daunting, but they can be programmed with CAM systems much more easily than before. These five-axis machines and multi-tasking lathes will enable the machining workshop to complete work faster and more accurately, as they can perform more tasks than traditional CNC equipment. Parts are more complete, with fewer errors - an important result to keep up with the current pace of the industry.

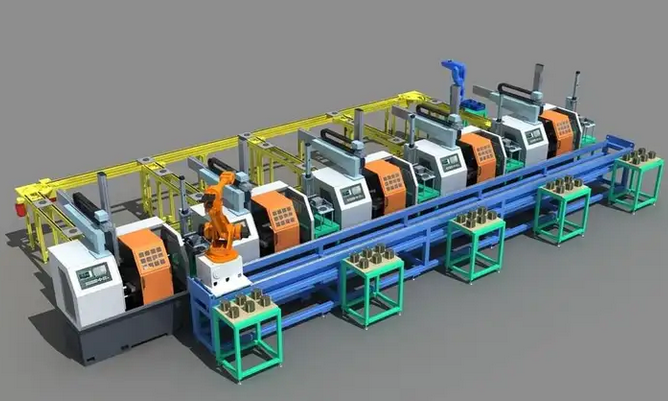

2. Robots and Automation

Automation technology is crucial for maintaining competitiveness. Skilled labor is hard to find, and we need to improve the efficiency of existing employees by eliminating repetitive tasks such as loading and unloading machines. Robots and automation greatly enhance the consistency of the workshop, thereby improving productivity and quality.

3. Coordinate Measuring Machines (CMM)

Nowadays, it is essential for workshops to have a three-coordinate measuring machine. These machines can handle difficult measurements. Three-coordinate measuring machines are crucial for accurately, consistently, and timely measuring parts. They can also automatically record measurement results to provide the necessary data for measurement proof when needed.

CNC workshops that embrace technological advancements, invest in workforce development, implement sustainable practices, offer customized solutions, maintain stringent quality control, and prioritize customer relationships will remain competitive in the future. By staying agile and innovative, these workshops can meet the evolving demands of the manufacturing industry and continue to thrive.