- Jun 18, 2024

When it comes to precision manufacturing, the choice of a CNC precision machining manufacturer can make all the difference in the quality, cost, and delivery time of your project. CNC (Computer Numerical Control) machining services have revolutionized the industry, offering unparalleled accuracy and efficiency. Here's how to choose the right CNC machine shop for your precision CNC machining needs.

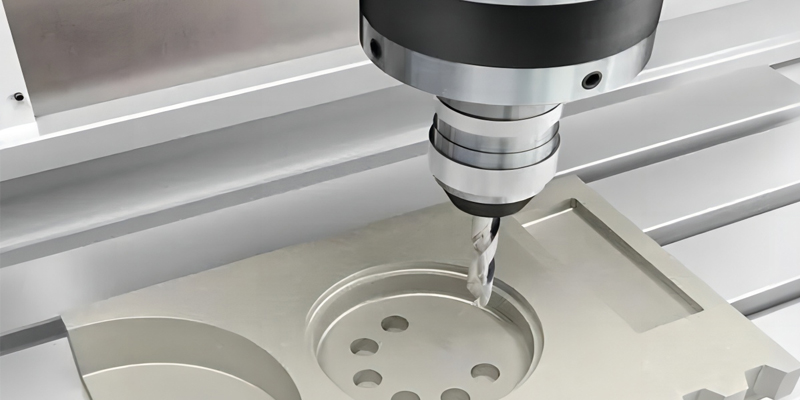

Precision CNC machining is the process of using computer-controlled machines to fabricate complex parts from raw materials. These machines can mill, turn, drill, and bore with high accuracy, making them ideal for producing parts for industries such as aerospace, automotive, medical, and electronics.

Key Factors to Consider When Choosing a CNC Machine Shop

1. Technical Expertise and Experience

Look for a CNC machine shop with a proven track record in handling projects similar to yours. Their expertise and experience should align with the complexity and requirements of your precision CNC machining needs.

2. Range of Services

Choose a CNC machining services provider that offers a comprehensive range of services, including prototyping, production runs, and post-machining operations such as grinding, polishing, and heat treatment.

3. Quality Assurance

A reliable CNC precision machining manufacturer will have robust quality control systems in place. Look for certifications such as ISO 9001 or AS9100, which demonstrate a commitment to quality management.

4. Advanced Equipment

The latest CNC machine tools are essential for achieving the highest levels of precision. Ensure the CNC machine shop utilizes state-of-the-art equipment that can handle the materials and tolerances required for your project.

5. Material Capabilities

Different projects require different materials. Choose a CNC machining services provider with experience in working with a variety of materials, including metals, plastics, and alloys.

6. Customization and Flexibility

The ability to customize and adapt to unique project requirements is crucial. A good CNC precision machining manufacturer should be flexible and responsive to your specific needs.

7. Lead Times and Reliability

Consider the manufacturer's lead times and their ability to meet deadlines. A reliable CNC machine shop will have a reputation for delivering projects on time without compromising on quality.

8. Communication and Customer Service

Effective communication is key to a successful partnership. Choose a CNC machining services provider with a customer-centric approach that keeps you informed throughout the project lifecycle.

9. Cost-Effectiveness

While cost is an important factor, it should not be the sole determinant. Look for a balance between quality, service, and price to ensure you get the best value for your investment.

Choosing the right CNC precision machining manufacturer is critical to the success of your project. By considering the factors outlined in this guide and following the steps to evaluate potential partners, you can find a CNC machine shop that meets your needs for quality, reliability, and cost-effectiveness. Remember, the right choice today can save you time, money, and resources in the long run, ensuring a successful outcome for your precision CNC machining projects.